How Does Molecular Sieve Pillow Pak Support Long-Term Drug Storage Requirements?

Maintaining the stability of moisture-sensitive pharmaceuticals during storage and transport is critical for efficacy and regulatory compliance. Molecular sieve pillow pak plays a crucial role in safeguarding drugs by controlling relative humidity, preventing hydrolysis, crystallization, and potency loss. Engineered with precise desiccant compounds and barrier materials, these pillow paks are tailored for high-value pharmaceuticals that demand stringent storage conditions. Their consistent performance across various storage scenarios ensures both product integrity and regulatory adherence.

Critical Desiccant Compounds in Pillow Paks

The effectiveness of a molecular sieve pillow pak depends on the desiccant chemistry:

- Type 3A and 4A molecular sieves: Highly selective for water molecules, providing robust protection for moisture-sensitive APIs. Their crystalline structure allows for rapid adsorption of moisture even in high-humidity conditions.

- Activated alumina: Adds complementary adsorption capacity and is compatible with neutral pH-sensitive formulations, preventing chemical interactions.

- Silica gel composites: Integrated for dual-phase adsorption, enhancing overall performance in variable environmental conditions and extending operational life of the desiccant.

- Barrier laminates and films: Medical-grade, multi-layer laminates create a vapor-impermeable seal, ensuring moisture does not infiltrate during long-term storage or transit.

By combining these compounds strategically, pillow paks maintain a controlled microenvironment, preventing degradation pathways in both solid and liquid dosage forms.

Optimized Design for Uniform Moisture Control

Design precision determines how effectively pillow paks protect pharmaceuticals:

- Even desiccant distribution prevents localized moisture pockets that can compromise stability.

- Shape and surface area optimization maximizes adsorption efficiency across container surfaces, ensuring uniform moisture capture.

- Sealing integrity with high-barrier laminates ensures consistent performance over multi-month storage cycles, reducing the need for frequent monitoring.

Extended design considerations also include layered pouches and venting structures to accommodate high-volume shipments while maintaining uniform humidity protection throughout the pallet or container.

Compliance with Pharmaceutical Standards

Molecular sieve pillow paks must meet rigorous pharma guidelines to be viable:

- GMP-aligned production: Guarantees consistent moisture adsorption capacity across batches.

- FDA packaging requirements: Ensure moisture thresholds are met and materials are inert with APIs.

- ICH Q1A/B stability testing: Confirms drugs retain potency and stability over long-term storage, including under accelerated conditions.

- Pharma-grade validation: Confirms all desiccant compounds, barrier materials, and packaging films are compatible with regulatory expectations and do not introduce contaminants.

Meeting these standards reduces regulatory risks, ensures batch-to-batch reliability, and aligns with global storage requirements for high-value pharmaceuticals.

Advantages for Long-Term Drug Storage

Using molecular sieve pillow paks provides measurable benefits for pharmaceutical storage:

- Extended shelf life: Protects against hydrolysis, crystallization, and potency loss.

- Maintained drug efficacy: Ensures APIs remain therapeutically active throughout their intended shelf life.

- Streamlined logistics: Reduces sensitivity to external humidity and temperature fluctuations, enabling flexible storage options.

- Scalable applications: Suitable for bulk shipments, multi-pallet transport, and multi-container storage without compromising performance.

These advantages are critical for manufacturers handling high-value biologics, vaccines, or temperature-sensitive solid and liquid formulations, where every unit’s integrity is paramount.

Verification and Monitoring of Desiccant Performance

Continuous monitoring ensures pillow pak efficiency over storage and transit periods:

- Humidity indicator cards: Provide visual confirmation of moisture ingress inside containers.

- Adsorption testing: Confirms the desiccant is performing within expected operational parameters.

- Sealing checks: Validate barrier integrity across multi-layer laminate films.

- Compatibility tests with APIs: Ensure no chemical interactions occur, protecting both potency and stability.

These measures support quality assurance programs and align with global regulatory expectations, ensuring that each pharmaceutical batch maintains its safety profile.

Selection Criteria for Pharmaceutical Applications

Choosing the correct pillow pak involves a detailed evaluation of multiple factors:

- Desiccant type and quantity: Must match moisture sensitivity of the specific drug formulation.

- Container material and dimensions: Influence adsorption efficiency and overall humidity control.

- Storage duration and environmental conditions: Determine the required desiccant load and barrier specifications.

- Regulatory compliance: Must meet GMP, FDA, and ICH standards to avoid storage-related quality failures.

Proper selection ensures optimal performance, minimizes degradation risk, and supports predictable shelf-life performance, even in complex distribution chains.

Integration Into Supply Chains

Molecular sieve pillow paks are designed for seamless integration into pharmaceutical packaging and logistics systems:

- Automated filling compatibility: Reduces handling errors and contamination risk during packaging.

- Predictable adsorption rates: Maintain consistent quality across shipments and batches.

- Multi-format adaptability: Compatible with bottles, cartons, and palletized shipments, enabling operational flexibility.

- Reduced operational intervention: Maintains regulatory compliance without additional monitoring or adjustments during transport.

These factors enable manufacturers to ensure product integrity while optimizing efficiency across the supply chain.

Final Note:

At Adsorbtek Solutions Inc., our molecular sieve pillow pak solutions are engineered for pharmaceuticals that require reliable long-term storage and regulatory compliance. By combining precise desiccant compounds like 3A and 4A molecular sieves, activated alumina, and silica gel composites with robust multi-layer barrier laminates, we ensure drug stability, prevent moisture ingress, and maintain controlled relative humidity. Our expertise extends to seamless integration into packaging lines and supply chain operations. Partner with us for advanced polyester coil desiccant packaging solutions designed to protect your products and preserve their quality throughout storage and transport.

Secure your moisture-sensitive pharmaceuticals with Adsorbtek Solutions Inc. today. Enhance long-term storage performance and regulatory compliance with our molecular sieve pillow pak solutions.

FAQs:

Q1: What is a molecular sieve pillow pak?

A molecular sieve pillow pak is a pharma-grade desiccant pouch designed to control humidity and protect moisture-sensitive drugs during storage and transport.

Q2: How does it support long-term drug storage?

It maintains a controlled microenvironment by adsorbing moisture, preventing hydrolysis, crystallization, and potency loss in pharmaceuticals.

Q3: What compounds are used in these pillow paks?

Common compounds include 3A/4A molecular sieves, activated alumina, and silica gel composites, combined with multi-layer barrier laminates.

Q4: Are molecular sieve pillow paks compliant with regulations?

Yes, they are manufactured according to GMP, FDA, and ICH guidelines, ensuring consistent performance and regulatory adherence.

Q5: How are pillow paks integrated into pharmaceutical packaging?

They can be incorporated into bottles, cartons, pallets, or containers, providing uniform humidity control throughout the supply chain.

Why Do Cosmetic Brands Choose Laminated Tubes for Cosmetics Over Plastic Tubes?

In modern cosmetic manufacturing, laminated tubes for cosmetics are preferred for their ability to maintain product integrity, comply with regulatory standards, and enhance consumer experience. Unlike conventional plastic tubes, laminated solutions use multi-layer composites and barrier technologies that prevent oxidation, moisture ingress, and microbial contamination, ensuring formulations remain stable throughout their lifecycle. These tubes also offer superior printability, allowing brands to convey their premium positioning effectively.

Multi-Layer Barrier Technology Protects Active Ingredients

Cosmetic formulations often contain sensitive compounds like vitamins, peptides, and essential oils that are highly reactive to environmental factors. Laminated tubes protect these ingredients through:

- Aluminum foil layers that block oxygen and light penetration

- Polyester (PET) and polyethylene layers providing structural strength and moisture resistance

- Barrier coatings preventing interaction with the cosmetic formulation

This multi-layer design ensures ingredients like retinol or ascorbic acid remain potent for extended periods. It also prevents oxidative reactions that can compromise fragrance, color, and texture.

Precision Dispensing Enhances User Experience

Packaging impacts not only safety but also consumer satisfaction. Laminated tubes offer:

- Controlled flow caps for accurate dispensing of creams and gels

- Consistent product texture delivery with minimal residue

- Flexible tube walls allowing full product usage without waste

Brands can customize dispensing mechanisms for high-viscosity formulations like hair gels or light creams. The precision dispensing reduces customer frustration while preserving hygiene, ensuring every use delivers consistent product performance.

Compliance-Driven Material Selection for Safety and Quality

Regulatory standards demand strict material compliance. Laminated tubes are manufactured considering:

- FDA and ISO-approved laminates for cosmetic use

- GMP-compliant production lines ensuring material traceability and hygiene

- Non-leaching adhesives and coatings compatible with both aqueous and oil-based formulations

Compliance extends beyond safety; it protects brands from potential recalls and ensures smooth entry into regulated markets, including the EU and North America. This reliability is critical for cosmetic lines with premium ingredients or patented formulations.

Customizable Design for High-Volume Manufacturing

Modern cosmetic production demands packaging that integrates with automated processes. Laminated tubes allow:

- Variable wall thicknesses to accommodate different viscosities

- Sealable nozzle tips for hygienic filling

- Compatibility with high-speed filling machines minimizing downtime and contamination risks

In addition, brands can select tube shapes, print finishes, and barrier layer combinations to differentiate their packaging in competitive retail environments, while maintaining functionality for mass production.

Durability and Stability During Distribution

During shipping, cosmetic products face temperature fluctuations and mechanical stress. Laminated tubes maintain stability by:

- Reinforced multi-layer construction preventing punctures and leaks

- Barrier protection against humidity and UV exposure

- Retention of fragrance, color, and texture throughout the supply chain

For international shipments, these tubes minimize degradation caused by variable climate conditions. They are particularly effective in protecting formulations containing volatile compounds or sensitive oils, which can react to oxygen or moisture.

Advanced Compounds in Laminated Tubes for Cosmetics

The effectiveness of laminated tubes depends on precise selection of compounds and processing:

- Aluminum foil provides exceptional oxygen and light barrier

- Polyethylene (PE) layers for chemical inertness and heat sealability

- Polyester (PET) layers adding mechanical strength and printability

- Adhesives and coatings ensuring laminate integrity without leaching into the product

- Optional barrier resins to increase resistance for highly reactive formulations

Additionally, some tubes incorporate siliconized inner layers to improve compatibility with active ingredients or UV-blocking pigments for extra protection. These compounds ensure high stability for cosmetic products requiring longer shelf life and rigorous transport conditions.

Why Leading Brands Trust Laminated Tubes

Laminated tubes are preferred because they combine efficiency, safety, and aesthetics. For cosmetic brands, the tubes are more than packaging; they are an extension of product quality. By selecting laminates that meet regulatory requirements, contain active ingredients safely, and support high-speed production, brands maintain consumer trust while reducing product losses.

Laminated tubes also allow brands to:

- Reduce waste and improve product utilization

- Offer differentiated designs for premium positioning

- Maintain consistency for multi-batch production

This combination of performance, compliance, and design flexibility explains why laminated tubes are becoming the standard in modern cosmetic packaging.

Final Look:

At Adsorbtek Solutions Inc., our laminated tubes for cosmetics are engineered to meet both cosmetic and pharmaceutical-grade packaging requirements. Using advanced laminates, barrier coatings, and validated sealing processes, we ensure products remain safe, stable, and visually appealing throughout their lifecycle. Our solutions meet the specific compound requirements for sensitive formulations while supporting high-volume production lines. For pharmaceutical applications, we also supply laminated tubes for pharma, engineered for strict compliance and long-term stability. Partner with us to safeguard your formulations and enhance consumer satisfaction.

Connect with Adsorbtek Solutions Inc. today to optimize your packaging and protect product integrity from production to end-use.

FAQs:

1. Why do cosmetic brands prefer laminated tubes over plastic tubes?

Laminated tubes provide superior barrier protection against oxygen, moisture, and light, ensuring product stability and longer shelf life.

2. What materials are used in laminated tubes for cosmetics?

Commonly used materials include aluminum foil, polyethylene, polyester, and specialized adhesives for chemical resistance and sealing.

3. Can laminated tubes handle sensitive formulations like vitamins or essential oils?

Yes, multi-layer laminates prevent degradation of sensitive ingredients, maintaining potency, fragrance, and texture during storage and shipping.

4. Are laminated tubes compatible with automated production lines?

They are designed for high-speed filling and sealing, with customizable wall thickness and nozzle configurations to suit different viscosities.

5. How do laminated tubes protect cosmetics during transport?

Multi-layer construction prevents leaks, punctures, and moisture ingress, ensuring products remain stable across varying temperature and humidity conditions.

Why Compliance-Driven Brands Partner With Proven Pharma Desiccant Suppliers

Maintaining moisture control in pharmaceutical products is not optional; it’s a compliance requirement. Pharma desiccant suppliers provide engineered solutions that prevent hydrolysis, oxidation, and microbial growth in sensitive drugs, ensuring active pharmaceutical ingredients (APIs) retain their stability throughout production, storage, and distribution. Effective moisture control safeguards product integrity, reduces recall risks, and ensures compliance with FDA and GMP guidelines. Additionally, these solutions streamline supply chains by mitigating risks associated with high-value or temperature-sensitive shipments.

Moisture Threats in High-Value Pharma Products

Even minor humidity variations can trigger chemical and physical degradation in drugs. Moisture risks include:

- Hydrolysis of APIs: Certain APIs, such as ampicillin and ceftriaxone, degrade rapidly when exposed to excess water, reducing potency.

- Excipient Instability: Lactose, starch, and other moisture-sensitive excipients can clump or dissolve unevenly, affecting dosage uniformity and formulation consistency.

- Packaging Weakness: Laminated tubes, blister packs, and high-barrier containers may fail if RH levels exceed recommended thresholds, impacting shelf life.

- Cross-Contamination Risk: Moisture can accelerate microbial growth in multi-drug storage, creating contamination hazards.

Pharma desiccants create a controlled microenvironment, maintaining stability across APIs and excipients, and complying with USP <671> and ICH Q1A stability standards.

Key Complexes Used in Pharma Desiccants

Pharmaceutical desiccants rely on precise chemical complexes for effective moisture absorption:

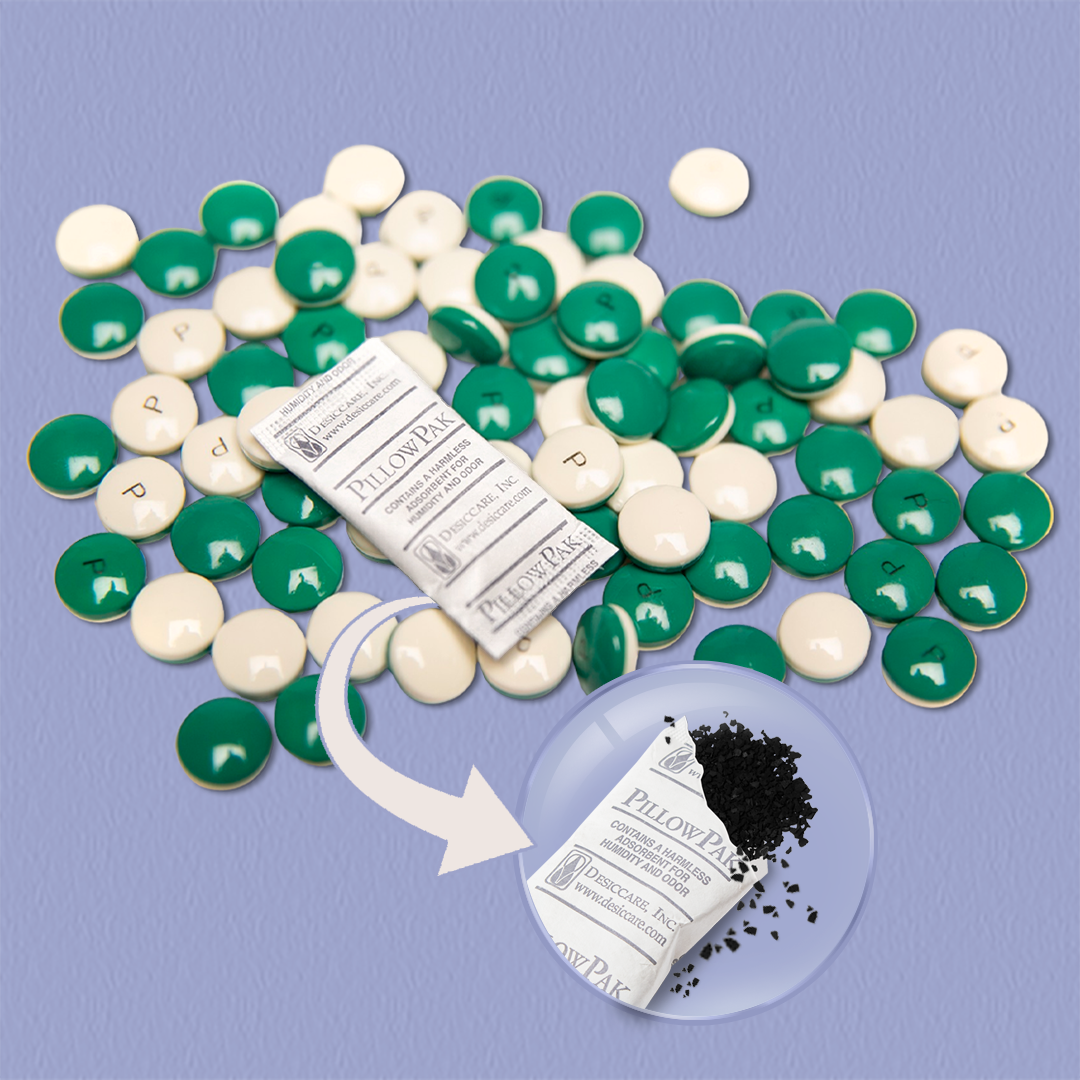

- Silica Gel: Provides high-capacity adsorption for both liquid and solid dosage forms, with color-indicating variants allowing visual monitoring of saturation levels.

- Molecular Sieves: Zeolite-based materials selectively adsorb water molecules, ideal for highly hygroscopic APIs and products requiring ultra-low moisture conditions.

- Calcium Oxide: Rapidly absorbs water in high-humidity environments, commonly paired with silica gel for multi-layer protection.

- Clay and Bentonite: Economical desiccants suitable for moderate moisture-sensitive products, commonly used in bulk packaging.

- Activated Carbon Additives: Remove residual moisture while controlling odors, particularly in multi-component formulations.

The correct combination of these complexes ensures tailored protection based on API sensitivity, storage conditions, and regulatory standards.

Compliance Essentials for Pharma Desiccant Applications

Brands rely on pharma desiccant suppliers to meet rigorous regulatory requirements:

- GMP Integration: Manufacturing, storage, and handling of desiccants must comply with ISO 9001 and WHO GMP protocols, ensuring process consistency.

- FDA Guidelines: Desiccants must be chemically inert, non-toxic, and validated to maintain moisture within defined limits.

- ICH Stability Testing: Validated performance across accelerated and long-term storage ensures desiccants consistently control relative humidity.

- Container Compatibility: Tubes, bottles, blister packs, and multi-pallet shipments must accommodate desiccants without compromising integrity or chemical stability.

Meeting these compliance essentials reduces the risk of regulatory action, product recalls, and financial loss.

Integrating Desiccants Into Packaging Lines

Efficient integration enhances desiccant performance and operational reliability:

- Automated Desiccant Insertion: Ensures consistent placement in multi-unit packaging, reducing human error and production downtime.

- Custom Unit Paks and Pillow Paks: Engineered to fit blister packs, bottles, and multi-pallet shipments, providing uniform moisture control across all units.

- Humidity Monitoring: Inline RH sensors enable real-time verification of environmental control, allowing proactive adjustments to desiccant placement or quantity.

- Layered Protection Strategies: Combining molecular sieve paks with silica gel canisters ensures redundancy, preventing moisture spikes even in complex packaging.

- Process Documentation: Maintaining validation logs for insertion, monitoring, and compliance supports audit readiness and regulatory traceability.

Operational Advantages of Trusted Suppliers

Partnering with experienced suppliers provides measurable business benefits:

- Reduced Product Loss: Proper moisture control prevents API degradation, batch rejection, and costly recalls.

- Regulatory Assurance: Solutions align with FDA, EMA, USP, and ICH guidelines, ensuring compliance in global markets.

- Scalable Solutions: Adaptable from small R&D batches to multi-pallet international shipments, facilitating supply chain flexibility.

- Technical Expertise: Suppliers provide guidance on chemical compatibility, packaging designs, and performance validation.

- Efficiency Gains: Optimized desiccant placement reduces material waste, labor costs, and potential downtime in production lines.

These advantages collectively strengthen product reliability, operational performance, and brand reputation.

Ending Note:

At Adsorbtek Solutions Inc., we deliver scientifically validated, regulation-ready solutions for moisture-sensitive pharmaceuticals. Our silica gel unit pak and molecular sieve designs are engineered to integrate seamlessly into production lines, meeting GMP, FDA, and ICH compliance requirements. From sensitive APIs to multi-pallet shipments, our desiccants maintain product integrity, extend shelf life, and enhance operational efficiency. Partner with us to implement tailored moisture-control strategies that protect your high-value pharmaceutical products while ensuring complete regulatory adherence.

Contact Adsorbtek Solutions Inc. to implement validated, compliance-driven pharma desiccant solutions today.

FAQs:

1. What are pharma desiccant suppliers?

Pharma desiccant suppliers provide engineered moisture-control solutions for pharmaceutical packaging to maintain product stability and compliance.

2. Why is moisture control critical in pharma products?

Moisture can degrade APIs, destabilize excipients, and reduce shelf life, affecting efficacy and regulatory compliance.

3. What types of desiccant complexes are used in pharmaceuticals?

Common complexes include silica gel, molecular sieves, activated carbon, calcium oxide, and bentonite, tailored to specific APIs.

4. How are desiccants integrated into packaging lines?

They are inserted as unit paks or pillow paks, with automated placement and humidity monitoring for consistent moisture control.

5. How do desiccant solutions support regulatory compliance?

They ensure stability under GMP, FDA, and ICH guidelines, supporting audits, documentation, and international shipment requirements.

What Quality Parameters Define Effective Silica Gel Canister Packaging?

Pharmaceutical products are extremely sensitive to moisture, which can trigger degradation, reduce efficacy, or compromise shelf life. Silica gel canister packaging is a critical component in maintaining product integrity throughout production, storage, and shipping. High-value APIs and moisture-sensitive excipients demand canisters that meet stringent quality standards, integrate effective desiccant complexes, and comply with GMP and FDA guidelines to ensure optimal protection. Properly engineered packaging safeguards your product while ensuring regulatory compliance and operational efficiency.

Material Integrity: The First Line of Defense

The packaging material itself determines how effectively a canister prevents moisture ingress. Modern silica gel canisters are engineered using:

- High-Density Polyethylene (HDPE) or Aluminium Alloys: Provide strong mechanical resistance and high moisture barrier properties.

- Chemical Inertness: Avoids interaction with APIs, excipients, or coating layers.

- USP <671> Compliance: Ensures the material meets pharmaceutical moisture permeability and stability standards.

Additional Considerations:

- Thickness uniformity affects absorption rates and structural resilience.

- Compatibility with sterilization methods like gamma radiation or autoclaving is essential for sensitive APIs.

- Surface smoothness and anti-static properties prevent adherence of powders or fine particulate formulations.

The combination of durable materials and chemical compatibility ensures the canister performs reliably under varying storage and transport conditions.

Desiccant Composition: Optimizing Adsorption

The desiccant inside the canister is the core functional element. Effective packaging leverages pharma-grade desiccant complexes, such as:

- Silica Gel: High surface area granules provide consistent moisture adsorption.

- Molecular Sieves: Capture trace moisture in highly sensitive APIs.

- Activated Carbon: Removes odors and volatile contaminants during storage.

- Calcium Oxide and Bentonite Blends: Act as supplementary moisture buffers for multi-layer packaging.

Technical Insights:

- Granule size and porosity directly impact adsorption kinetics.

- Layered desiccant arrangements optimize airflow and moisture capture efficiency.

- Moisture indicators integrated within the desiccant allow visual verification of performance.

These complexes are selected based on API sensitivity, storage conditions, and shelf-life requirements, ensuring uniform performance over time.

Canister Design: Balancing Functionality and Efficiency

Packaging design impacts adsorption efficiency and overall protection. Quality canisters feature:

- Optimized Internal Geometry: Ensures even airflow and prevents channeling of moisture.

- Sealing Mechanisms: Screw caps, snap-fit closures, or vacuum-sealed lids maintain airtight conditions.

- Stacking and Handling Features: Reduces the risk of deformation or leakage during transport.

Design Sub-Pointers:

- Internal ridges and baffles direct moisture evenly across the desiccant bed.

- Multi-layer seals enhance redundancy and extend shelf-life under extreme conditions.

- Transparent or semi-transparent bodies allow inspection without opening the canister.

Designing for consistent performance across multiple batches is crucial for GMP-compliant pharmaceutical packaging.

Regulatory Compliance: Meeting Pharma Standards

Compliance is non-negotiable in pharmaceutical packaging. Critical regulatory considerations include:

- GMP Guidelines: Ensures reproducible moisture control and packaging validation.

- FDA Requirements: Canisters must meet safety, labeling, and documentation standards.

- ICH Stability Protocols (Q1A & Q1B): Packaging must maintain controlled humidity during stability testing.

Additional Compliance Measures:

- Batch traceability ensures accountability from production to distribution.

- Documentation must include desiccant weight, adsorption capacity, and seal integrity test results.

- Temperature and humidity cycling tests confirm stability under transit and storage conditions.

Every canister must be traceable, validated, and supported by documented QA protocols to meet audits and inspections.

Performance Verification: Metrics for Quality Assurance

Routine monitoring ensures canisters consistently deliver performance. Key QA parameters include:

- Humidity Sensors: Track relative humidity within the canister during storage.

- Weight and Adsorption Testing: Confirms silica gel and molecular sieves maintain absorption capacity.

- Visual Inspection: Detects moisture ingress, discoloration, or desiccant clumping.

Verification Sub-Pointers:

- Periodic re-testing of desiccant adsorption ensures consistent moisture control over multiple shipments.

- Shelf-life simulations help predict canister performance under high-humidity conditions.

- Instrumentation like moisture analyzers or gravimetric testing validates batch performance.

These verification measures reduce risk, ensure compliance, and guarantee API stability from production to end-user delivery.

Customization for Pharmaceutical Requirements

Advanced silica gel canister packaging adapts to product-specific needs. Parameters for customization include:

- Dosage Form Sensitivity: Powdered APIs vs. liquid formulations require different desiccant loads.

- Environmental Conditions: High-humidity regions demand higher adsorption capacity.

- Container Size and Volume: Optimized to ensure uniform desiccant distribution and product protection.

Optimization Strategies:

- A combination of molecular sieves with silica gel enhances performance for ultra-sensitive APIs.

- Integrated moisture indicators and color-changing desiccants allow easy field verification.

- Custom fill volumes prevent excessive headspace, which can reduce adsorption efficiency.

Custom solutions enhance operational efficiency while maintaining consistent moisture control across diverse supply chains.

Closing Note:

Selecting effective silica gel pillow pak solutions requires expertise in material selection, desiccant complexes, design, and compliance. At Adsorbtek Solutions Inc., we combine silica gel, molecular sieves, activated carbon, and calcium oxide in carefully engineered canisters that meet GMP and FDA standards. Our solutions ensure predictable moisture control, protect sensitive APIs, and deliver robust performance across production, storage, and shipping. Partner with us to optimize your packaging lines and safeguard pharmaceutical products from degradation and moisture-related failures.

FAQs:

1. What is the role of silica gel canister packaging in pharma products?

It maintains low humidity inside containers, preventing degradation of moisture-sensitive APIs and extending shelf life.

2. Which desiccant compounds are commonly used in canisters?

Silica gel, molecular sieves, activated carbon, and calcium oxide are standard to ensure optimal moisture control.

3. How does canister design affect performance?

Internal geometry, sealing mechanisms, and material integrity ensure uniform moisture absorption and prevent ingress during storage and transit.

4. What regulatory standards must effective canisters meet?

GMP compliance, FDA packaging guidelines, and ICH stability protocols ensure safety, reliability, and validated performance.

5. How can the performance of silica gel canisters be verified?

Humidity sensors, adsorption capacity testing, and visual inspection confirm consistent moisture control across batches.

How Does Adsorbent Quality Influence Activated Carbon Desiccant Packaging Performance?

Activated carbon desiccant packaging plays a vital role in protecting moisture-sensitive products during storage and transit. Its effectiveness relies heavily on the quality of the adsorbent used. High-grade activated carbon ensures efficient moisture and odor adsorption, maintaining product stability and extending shelf life. In industries like pharmaceuticals, nutraceuticals, and food products, even slight moisture penetration can compromise product integrity. This makes choosing the right adsorbent critical for ensuring consistent quality throughout the supply chain. Using premium adsorbent materials in desiccant packaging also prevents contamination and maintains the product's original properties. Poor-quality carbon can introduce impurities, reducing effectiveness and potentially affecting product safety. Reliable activated carbon desiccant packaging ensures sensitive goods remain safe, dry, and ready for use, even under challenging environmental conditions.

How Adsorbent Purity Affects Performance

The purity of activated carbon determines how well the desiccant can trap moisture and contaminants. Impurities can reduce adsorption efficiency, compromising product safety. Using high-purity adsorbents minimizes the risk of chemical interactions and maintains consistent performance, especially in critical industries like pharmaceuticals and nutraceuticals.

- Enhanced Absorption: High-quality carbon offers a larger surface area for moisture and gas adsorption.

- Reduced Contaminants: Purity prevents leaching of unwanted substances into the packaged product.

- Consistent Results: Reliable performance ensures predictable protection across multiple shipments.

High-purity carbon is particularly essential for pharmaceutical packaging, where maintaining sterility and preventing chemical interference is mandatory. Even minor impurities can compromise regulatory compliance, highlighting the importance of adsorbent quality in packaging solutions.

Particle Size and Adsorption Efficiency

Particle size significantly impacts the adsorption rate in activated carbon desiccant packaging. Smaller particles provide greater surface area, improving moisture capture, but may create higher airflow resistance. Optimal particle size balances adsorption efficiency and package compatibility, ensuring uniform protection without affecting container handling.

- Fine particles: High absorption, slower airflow.

- Medium particles: Balanced performance, optimal for most packaging.

- Coarse particles: Lower absorption, faster airflow.

Choosing the right particle size also influences how quickly the desiccant responds to sudden humidity changes. For shipping over long distances or in variable climates, the correct particle size ensures that moisture is absorbed rapidly, protecting sensitive goods from degradation.

The Role of Surface Area and Porosity

Adsorbent performance depends on surface area and porosity. Activated carbon with a highly porous structure traps moisture, gases, and odors effectively. Higher porosity improves the desiccant’s ability to maintain stable relative humidity inside the package, essential for sensitive products during long-distance shipping.

- Micropores: Capture moisture at a molecular level.

- Mesopores: Adsorb larger molecules and odors.

- Macropores: Allow efficient airflow and distribution.

Products like pharmaceuticals, nutraceuticals, and electronics require precise moisture control. Adsorbents with high surface area and optimal pore distribution provide consistent protection, ensuring goods arrive in their original quality. By selecting carbon with tailored porosity, packaging performance can meet specific product needs.

Quality Standards and Compliance

High-quality activated carbon desiccant packaging must comply with international standards to guarantee safety and reliability. Compliance with FDA, USP, and ISO guidelines ensures the desiccant is free from toxic residues, safe for contact with pharmaceuticals, and performs as intended under variable storage conditions.

- FDA 21 CFR: Ensures safety for pharma packaging.

- USP <670>: Confirms moisture protection standards.

- ISO 9001: Guarantees manufacturing consistency and quality control.

Compliance also builds trust with clients and regulators, confirming that the adsorbent used in packaging adheres to strict quality benchmarks. It is essential for companies shipping sensitive products internationally, where regional regulations vary.

How Adsorbent Stability Impacts Long-Term Storage

Adsorbent stability is critical for long-term storage of moisture-sensitive products. Low-quality carbon may degrade or lose adsorption capacity over time, exposing contents to moisture and odors. High-quality activated carbon ensures stable performance throughout the product lifecycle, maintaining efficacy until the point of use.

- Long shelf life: Consistent adsorption over months.

- Reliable protection: Avoids premature moisture damage.

- Storage resilience: Performs well under fluctuating temperature and humidity.

Maintaining stability is particularly important for products with long distribution chains. Reliable adsorbents prevent spoilage, reducing waste and preserving brand reputation. Selecting a desiccant with high structural integrity ensures that it continues to perform optimally, regardless of storage conditions.

Final Thoughts:

High-grade adsorbent quality directly affects activated carbon desiccant packaging performance. At Adsorbtek Solutions Inc., our focus is on delivering premium desiccant solutions that safeguard moisture-sensitive goods during storage and shipping. By using adsorbents that meet strict quality and compliance standards, our packaging solutions protect products from moisture, odors, and contamination throughout their lifecycle. Our desiccant packs for containers are designed to maintain product integrity under various environmental conditions, giving businesses confidence in their logistics and storage processes.

Contact Adsorbtek Solutions Inc. today to explore our superior activated carbon desiccant packaging solutions tailored to your shipping and storage requirements.

FAQs:

1. What is activated carbon desiccant packaging?

Activated carbon desiccant packaging is designed to absorb moisture and odors, protecting sensitive products during storage and transport.

2. Why does adsorbent quality matter in desiccants?

High-quality adsorbents ensure consistent moisture control, prevent contamination, and maintain product stability over time.

3. How does particle size affect desiccant performance?

Smaller particles increase surface area for adsorption, while optimal sizing balances efficiency and airflow inside packaging.

4. What compliance standards apply to desiccant packaging?

Standards like FDA 21 CFR, USP <670>, and ISO ensure safety, performance, and suitability for pharmaceuticals.

5. Can activated carbon desiccants maintain long-term product integrity?

Yes, premium desiccants remain stable and effective over extended storage, safeguarding moisture-sensitive items until use.

Why Is Tensile Strength Important in Cotton Coil Packaging for Pharma?

Maintaining product integrity during storage and transport is crucial in the pharmaceutical sector. Cotton coil packaging plays a significant role in ensuring the safety of sensitive pharmaceutical products. One of the critical factors determining the effectiveness of this packaging is tensile strength. Strong and reliable packaging protects medicines from mechanical stress and environmental factors, preserving their quality and shelf life. Additionally, tensile strength ensures uniformity across all packaging rolls, allowing for predictable handling and storage performance across production batches. This consistency is vital for pharmaceuticals that require strict adherence to safety and efficacy standards.

Understanding Tensile Strength in Pharmaceutical Packaging

Tensile strength measures how much pulling force a material can withstand before breaking. In cotton coil packaging, this property ensures that the packaging remains intact during handling, transport, and storage. High tensile strength prevents tearing, stretching, or puncturing, which could expose products to contamination or moisture. For pharmaceutical products, even minor damage can compromise efficacy and safety.

- Durability Under Stress: Packaging must endure physical stress during shipping, storage, and handling. Strong coils reduce the risk of tearing during stacking and movement.

- Consistency Across Batches: Uniform tensile strength ensures that every roll of cotton coils maintains reliable protection, reducing variability in product safety.

- Enhanced Shelf Life: Strong packaging reduces exposure to environmental factors, preserving product integrity for long-term storage and distribution.

- Protection Against Mishandling: Tensile strength allows the packaging to withstand accidental drops, impacts, or friction during loading and unloading operations.

Key Factors Affecting Tensile Strength

Several elements influence the tensile strength of cotton coil packaging. Understanding these factors helps manufacturers choose the right materials and processes for optimal protection.

- Material Quality: High-grade cotton fibers increase resistance to tearing and punctures, ensuring longer-lasting protection.

- Weaving and Density: Tightly woven coils enhance structural integrity and load-bearing capacity, preventing deformation under pressure.

- Moisture Content: Properly dried cotton prevents weakening of fibers over time, maintaining strength during shipping and storage.

- Treatment and Coating: Protective coatings or treatments can enhance tensile properties, improve barrier performance, and maintain hygiene standards.

- Storage Conditions: Environmental factors, such as temperature and humidity, can affect tensile properties; consistent storage ensures packaging remains reliable.

Compliance and Industry Standards

Pharmaceutical packaging must adhere to strict regulatory requirements. Ensuring the correct tensile strength aligns with industry standards for safety and quality, including FDA and USP regulations. Compliance with these standards is critical for maintaining the stability of drugs, avoiding contamination, and achieving approval for distribution.

- FDA 21 CFR Compliance: Ensures packaging materials meet safety criteria for pharmaceutical use.

- USP <661> Testing: Confirms integrity and strength of packaging under stress conditions, maintaining product safety.

- ISO Standards: Provides consistent quality metrics for tensile strength and material durability, ensuring predictable performance across shipments.

- Regular Quality Audits: Monitoring tensile strength through routine tests supports regulatory compliance and reduces the risk of product recalls.

Impact of Tensile Strength on Product Protection

Proper tensile strength in cotton coil packaging reduces the risk of product loss or contamination. During transport, pharmaceutical products face vibrations, stacking pressure, and environmental changes. Strong coils act as a protective layer, cushioning the contents and maintaining barrier properties.

- Mechanical Protection: Reduces tearing or punctures from rough handling and transportation hazards.

- Moisture Control: Maintains barrier effectiveness against humidity or condensation, preventing degradation of sensitive medicines.

- Safe Handling: Supports easier handling for operators, reduces accidental damage, and ensures smooth operations during logistics.

- Enhanced Stability: Packaging with proper tensile strength maintains form and function, even under extended storage periods or long supply chains.

Choosing the Right Cotton Coil Packaging

Selecting packaging with appropriate tensile strength requires careful evaluation of product type, shipment conditions, and storage requirements. Pharmaceutical manufacturers often conduct tensile testing and quality inspections to ensure each batch meets required performance levels.

- Testing Protocols: Standardized tensile tests validate material performance and ensure consistency across batches.

- Custom Specifications: Coil density, thickness, and fiber quality can be tailored according to product fragility and handling conditions.

- Long-Term Storage: High-strength coils maintain durability over extended periods under controlled environmental conditions.

- Supplier Selection: Choosing experienced suppliers ensures adherence to industry standards and consistent product quality.

Final Note:

Strong tensile strength in cotton coil packaging is not just a technical specification; it directly influences product safety and reliability. At Adsorbtek Solutions Inc., our approach ensures high-quality cotton coils that meet stringent compliance standards and deliver consistent protection. Our packaging solutions are designed to handle the demands of pharmaceutical transport and storage while maintaining product integrity. We ensure that every roll meets regulatory standards and tensile performance metrics, giving our clients peace of mind. With our expertise, pharmaceutical companies can rely on cotton coils for bottle packaging to safeguard their products through every stage of distribution.

Protect your pharmaceutical products with reliable cotton coil packaging. Contact Adsorbtek Solutions Inc. today for customized solutions designed to meet your safety and compliance needs.

FAQs:

1. What is the tensile strength in cotton coil packaging?

Tensile strength measures the force a cotton coil can withstand before breaking, ensuring product protection during handling and transport.

2. Why is tensile strength critical for pharmaceuticals?

High tensile strength prevents tearing or punctures, maintaining product integrity and avoiding contamination or degradation.

3. How is tensile strength tested in cotton coil packaging?

Standardized tensile tests evaluate fiber quality, coil density, and material performance to ensure consistency across batches.

4. Can packaging tensile strength affect shelf life?

Yes, stronger coils reduce exposure to environmental stress, preserving the stability and efficacy of pharmaceutical products.

5. What standards ensure proper tensile strength in packaging?

Compliance with FDA 21 CFR, USP <661>, and ISO standards guarantees safe and reliable cotton coil packaging.

How Does Cargo Desiccant Packaging Protect Against Seasonal Humidity Changes?

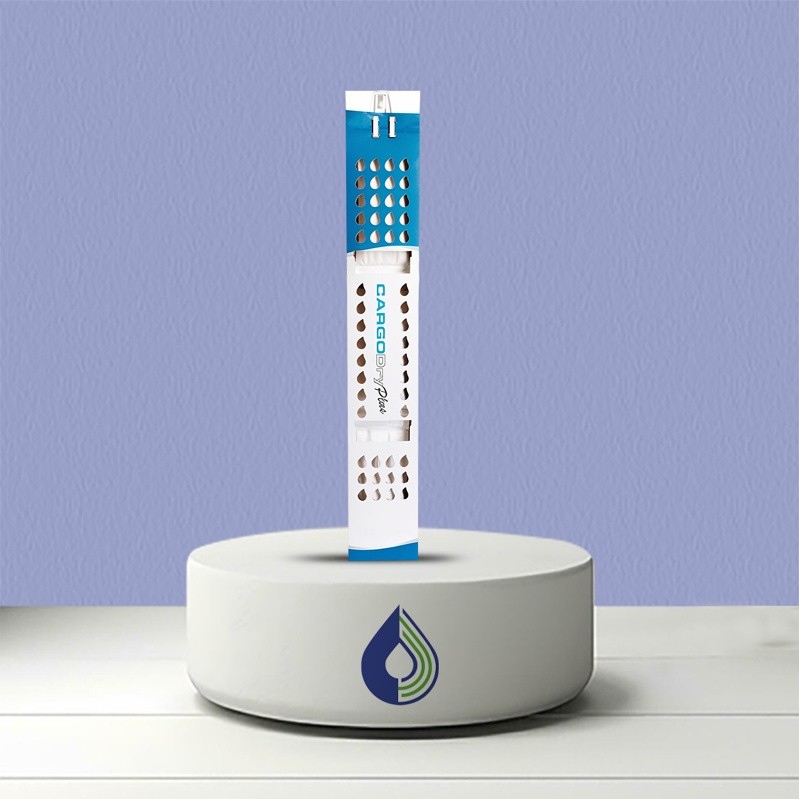

Maintaining product integrity during transit is crucial, and cargo desiccant packaging plays a vital role in shielding shipments from fluctuating humidity. Seasonal changes can cause moisture variations that compromise product quality, making effective moisture control essential for sensitive goods. Properly designed desiccant packaging adapts to a wide range of environmental conditions, offering a reliable solution for global shipping needs.

Understanding Seasonal Humidity Challenges

- Humidity spikes: High moisture levels during rainy or humid seasons can accelerate corrosion, mold growth, and product degradation.

- Low humidity impacts: Dry seasons can cause packaging shrinkage or material brittleness, leading to potential leaks or contamination.

- Temperature fluctuations: Changes in temperature amplify humidity effects, stressing conventional packaging systems.

By understanding these challenges, businesses can deploy targeted moisture control strategies that maintain product quality throughout transit. Seasonal variations are often unpredictable, and even short-term exposure to high or low humidity can compromise product safety. For sensitive shipments, recognizing these risks is the first step toward robust moisture management.

Mechanism of Cargo Desiccant Packaging

- Moisture adsorption: Desiccants absorb excess moisture inside containers, preventing condensation and damp conditions.

- Humidity stabilization: They maintain an optimal internal environment, protecting products from seasonal swings in moisture.

- Material compatibility: Desiccants are engineered to work with various cargo types, including pharmaceuticals, electronics, and food items.

The absorption process involves a chemical or physical reaction between the desiccant material and water molecules, ensuring consistent humidity control. This mechanism ensures sensitive goods are transported safely, reducing risks associated with seasonal humidity fluctuations. In addition, the right packaging design complements desiccant efficiency, helping to maximize moisture protection across the entire shipment.

Types of Desiccants Used in Cargo Packaging

- Silica gel: Highly effective for general moisture absorption, suitable for most shipping conditions.

- Clay-based desiccants: Ideal for moderate moisture control in bulk shipments.

- Molecular sieves: Specialized for extreme humidity conditions, offering consistent performance under challenging climates.

- Activated carbon blends: Provide dual protection by adsorbing moisture and reducing odors or chemical vapors.

Selecting the correct desiccant type based on shipment requirements ensures consistent performance and product protection. Different desiccants have unique moisture adsorption rates and capacities, making it important to consider factors like container size, transit duration, and seasonal conditions. Using multiple desiccant types together can also enhance protection, creating a layered defense against moisture.

Testing and Compliance Standards

- Moisture Vapor Transmission Rate (WVTR) tests: Evaluate packaging efficiency in blocking moisture penetration.

- Container integrity tests: Ensure seals and packaging materials withstand seasonal stress.

- Regulatory compliance: Packaging meets standards such as U.S. FDA, EU Food Safety, and international shipping guidelines.

Regular testing guarantees that desiccants and packaging perform effectively under varying seasonal conditions. It also helps businesses monitor desiccant performance over time, making adjustments for shipments exposed to extreme humidity or long transit periods. Compliance with global standards ensures that cargo meets regulatory expectations and minimizes the risk of product recalls.

Benefits of Effective Cargo Desiccant Packaging

- Preserved product quality: Prevents moisture-induced damage, ensuring shipments arrive intact.

- Reduced returns and losses: Minimizes spoilage or rejection due to humidity-related issues.

- Extended shelf life: Maintains stability for sensitive products such as biologics, nutraceuticals, and electronics.

- Operational efficiency: Reduces the need for emergency interventions or repackaging during transit.

These benefits make cargo desiccant packaging a critical investment for businesses managing seasonal shipments. Companies that use advanced desiccant solutions can maintain customer satisfaction and reduce operational costs caused by moisture-related damages.

Best Practices for Seasonal Shipping

- Optimal desiccant placement: Positioning desiccants near moisture-sensitive areas enhances protection.

- Container monitoring: Use data loggers to track humidity changes and desiccant performance in transit.

- Pre-conditioning shipments: Adjust packaging environment to reduce exposure to extreme seasonal moisture changes.

- Proper storage before shipping: Maintain containers in controlled conditions to maximize desiccant efficiency.

Following these practices ensures maximum protection from seasonal humidity effects. Proper planning also helps anticipate environmental changes during transit, allowing businesses to choose the most suitable desiccant type and quantity for each shipment.

Ending Note:

Our cargo dry plus packaging solutions are designed to adapt to seasonal variations, offering reliable moisture control across global supply chains. At Adsorbtek Solutions Inc., our focus is on providing packaging systems that maintain product integrity, extend shelf life, and protect against environmental fluctuations. With customized cargo desiccant packaging, businesses can manage seasonal humidity effectively, ensuring consistent product quality while reducing losses and compliance risks.

Strengthen your shipments against seasonal humidity. Contact Adsorbtek Solutions Inc. for tailored cargo desiccant packaging solutions today.

FAQs:

What is cargo desiccant packaging?

Cargo desiccant packaging uses moisture-absorbing materials to maintain stable humidity, protecting sensitive goods during transit.

How does it protect products from seasonal humidity?

Desiccants absorb excess moisture and stabilize internal conditions, preventing spoilage or damage during fluctuating humidity.

Which industries benefit most from desiccant packaging?

Pharmaceuticals, nutraceuticals, electronics, and food shipments benefit, as they are highly sensitive to moisture changes.

What types of desiccants are commonly used?

Silica gel, clay-based desiccants, molecular sieves, and activated carbon blends provide different levels of moisture control.

How can I monitor desiccant effectiveness during transit?

Humidity data loggers and container testing help track performance, ensuring products remain protected throughout shipping.

How Can Pharmaceutical Packaging Solutions Reduce Contamination Risks

Pharmaceutical packaging solutions play a critical role in ensuring the safety and efficacy of medicines by minimizing exposure to contaminants. In the pharmaceutical industry, protecting formulations from moisture, dust, microbes, and chemical interference is essential. Advanced packaging methods create a controlled barrier, maintaining product stability from manufacturing through delivery. Proper packaging reduces spoilage, preserves potency, and guarantees patient safety, making it a fundamental part of pharmaceutical supply chains.

Ensuring Hygienic Packaging Environments

Maintaining a sterile environment during packaging is vital for contamination control. Controlled humidity, filtered air, and cleanroom practices prevent microbial and particulate intrusion. Using high-quality pharmaceutical packaging materials ensures that external elements cannot penetrate, safeguarding sensitive tablets, capsules, injectables, and powders.

- Employing cleanroom-approved packaging materials minimizes dust and microbial contamination.

- Sealing mechanisms prevent air and particle ingress, maintaining formulation integrity.

- Incorporating microbial-resistant coatings provides additional protection for moisture-sensitive drugs.

Routine monitoring of cleanroom environments and strict adherence to GMP standards ensure that pharmaceutical products are packaged under conditions that reduce the risk of contamination at every stage.

Barrier Properties and Material Selection

Packaging materials with superior barrier properties are essential to prevent contamination. Multi-layer laminates, high-density plastics, and aluminum foils effectively block moisture, oxygen, and light, which can compromise drug stability. Selecting the correct material based on formulation type ensures longer shelf life and minimizes degradation risks.

- Aluminum and laminated barriers protect light-sensitive and hygroscopic compounds.

- Plastic containers with low permeability safeguard formulations prone to moisture absorption.

- Combination materials, such as foil-plastic laminates, provide maximum chemical and physical protection.

Choosing the right material depends on the type of pharmaceutical product, its shelf-life requirements, and storage conditions, ensuring consistent performance from packaging to patient delivery.

Tamper-Evident Features for Safety

Incorporating tamper-evident elements is critical for preventing contamination and ensuring integrity during handling and transit. Seals, caps, and closures designed to show evidence of interference provide assurance that the medication remains untouched and uncontaminated until use.

- Breakable seals on bottles and vials clearly indicate any unauthorized opening.

- Shrink bands add an additional visible layer of protection.

- Visible indicators on closures alert consumers to tampering, ensuring confidence and safety.

Tamper-evident features also support regulatory compliance, meeting requirements for safe pharmaceutical packaging while protecting brand integrity and patient trust.

Controlled Atmosphere and Moisture Management

Pharmaceutical packaging solutions often integrate moisture and oxygen control systems to maintain product stability. Desiccants, oxygen absorbers, and vacuum-sealed containers protect formulations from environmental factors. These measures prevent microbial growth, chemical reactions, and physical changes that could compromise product safety.

- Silica gel and molecular sieve canisters manage humidity inside containers.

- Oxygen scavengers prevent oxidation in highly sensitive formulations.

- Vacuum-sealed and inert gas-flushed packaging reduces the chance of contamination during shipping and storage.

These systems are especially critical for biologics, nutraceuticals, and moisture-sensitive medications, where even minor exposure can alter potency or cause degradation.

Rigorous Testing and Compliance

Regular testing ensures that packaging solutions meet contamination prevention standards. Barrier integrity, mechanical strength, and microbial resistance are evaluated to guarantee compliance with regulatory requirements. Adherence to FDA, USP, and EU guidelines provides assurance that packaging maintains safety during storage and distribution.

- Leak and burst testing confirms container integrity under stress.

- Microbial challenge tests validate the effectiveness of barrier and closure systems.

- Compliance with U.S. FDA 21 CFR, USP <671>, and EU regulations ensures global standards are met.

By conducting these tests routinely, manufacturers can identify potential vulnerabilities in packaging design and make necessary improvements to reduce contamination risks.

Logistics and Transportation Considerations

Pharmaceutical products are exposed to varying environmental conditions during transit. Advanced packaging solutions mitigate contamination risks by maintaining controlled internal conditions. Properly designed shipping containers and desiccant systems ensure that medications remain stable across global distribution channels.

- Shock-absorbing designs prevent physical damage to containers during handling.

- Temperature-stable packaging maintains efficacy for thermosensitive formulations.

- Desiccant integration protects moisture-sensitive drugs from humidity variations in shipping environments.

Monitoring and selecting packaging solutions tailored to specific transit requirements is crucial for preserving drug quality and preventing contamination before reaching healthcare providers and patients.

Enhancing Shelf Life and Product Quality

Effective pharmaceutical packaging solutions directly enhance shelf life and maintain product quality. By controlling environmental exposure, preventing microbial contamination, and protecting against physical damage, medicines retain their intended potency and safety profile throughout their lifecycle.

- Optimized barrier selection ensures maximum protection for each formulation.

- Desiccant integration reduces the risk of degradation in moisture-sensitive drugs.

- Tamper-proof features maintain product safety and regulatory compliance.

Maintaining consistent performance across storage and transport conditions ensures patients receive medications that meet the highest safety standards.

Closing Note:

At Adsorbtek Solutions Inc., our pharmaceutical packaging solutions are engineered to reduce contamination risks at every stage, from manufacturing to delivery. By combining advanced barrier technologies, tamper-evident systems, and controlled moisture management, we ensure the stability, safety, and compliance of your formulations. Our shipping desiccant packaging solutions provide reliable protection, enhancing product shelf life and maintaining quality across global distribution networks. Contact us today to optimize your pharmaceutical packaging strategies and safeguard your products.

FAQs:

1. What are pharmaceutical packaging solutions?

Pharmaceutical packaging solutions are materials and systems designed to protect medicines from contamination, moisture, and environmental damage during storage and transit.

2. How do packaging solutions prevent contamination?

They use barriers, tamper-evident seals, and controlled atmosphere systems to block microbes, moisture, and external pollutants.

3. Why is barrier integrity important in pharmaceutical packaging?

Barrier integrity ensures drugs remain stable and safe, preventing degradation or potency loss over their shelf life.

4. What role do desiccants play in packaging?

Desiccants manage moisture levels inside containers, protecting sensitive formulations from humidity-induced spoilage.

5. How does testing ensure packaging effectiveness?

Regular testing of seals, barrier strength, and microbial resistance verifies that packaging maintains safety and compliance standards.

Search

Recent Posts