How Can Molecular Sieve Unit Pak Improve Shelf Life Consistency Across Global Distribution?

Pharmaceutical and moisture-sensitive products face significant challenges during long-distance shipping. Controlled humidity is crucial to prevent degradation, hydrolysis, or reduced potency of active ingredients. Molecular sieve unit pak provides reliable moisture adsorption in varying climatic conditions, ensuring product integrity throughout global distribution channels.

Precise Moisture Adsorption for Extended Shelf Life

Humidity fluctuations during storage and transport can accelerate chemical reactions, especially in hygroscopic APIs and nutraceuticals. Molecular sieve unit packs are engineered with high-quality zeolites capable of adsorbing water molecules even at low relative humidity.

- Maintains internal container RH within safe limits

- Protects moisture-sensitive formulations, powders, and tablets

- Reduces hydrolytic degradation, extending product shelf life

By maintaining micro-environmental stability, these unit paks support consistent drug efficacy during transit and storage, aligned with USP and ICH stability requirements.

Optimized Design for Container Integration

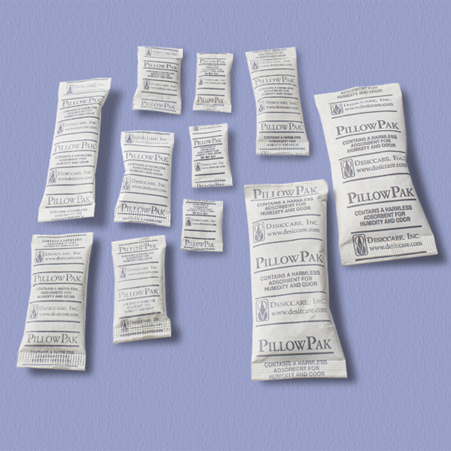

Efficient distribution relies on consistent packaging performance. The molecular sieve unit pack is designed to fit seamlessly into bottles, drums, or bulk containers without compromising workflow.

- Compact sizing ensures even placement in container spaces

- Non-toxic, stable materials compatible with pharmaceutical packaging

- Unit-based options provide scalability for varying container volumes

This modular approach allows manufacturers to customize moisture control for different shipment sizes, guaranteeing uniform protection. The uniform design also minimizes the risk of movement during transit, preventing uneven adsorption and maintaining product integrity.

Performance Under Extreme Conditions

Global distribution exposes products to temperature and humidity extremes, from tropical heat to arid cold storage environments. Molecular sieve unit paks maintain adsorption capacity across a wide temperature range, ensuring products reach end-users in optimal condition.

- High thermal stability prevents collapse or loss of adsorption capacity

- Maintains consistent moisture control across multiple transit points

- Compatible with both automated filling lines and manual packaging

Studies on international shipments demonstrate that molecular sieve unit paks maintain internal RH below critical thresholds during multi-week sea and air transport, effectively preventing condensation and microbial growth in packaging.

Compliance With Regulatory Standards

For pharmaceutical applications, adherence to FDA, EU, and military standards is essential. Molecular sieve unit packs are manufactured under strict quality control protocols, meeting global regulatory requirements.

- U.S. FDA approved for safe use in pharmaceutical and nutraceutical packaging

- Compliant with EU regulations and RoHS standards

- Supports documentation for GMP and ICH stability protocols

Such compliance ensures that packaging solutions not only protect products but also support regulatory inspections and audits. These validations are particularly critical for biologics, probiotics, and semi-solid formulations where moisture sensitivity is high.

Integration With Automated Packaging Systems

Modern production lines require desiccants that are compatible with automated filling, capping, and sealing machinery. Molecular sieve unit paks are engineered for uniform size and mechanical stability, allowing seamless integration into high-speed workflows.

- Consistent weight and dimensions facilitate robotic placement

- Reduces downtime caused by desiccant misalignment or spillage

- Compatible with standard bottle types, drums, and bulk containers

Automation support helps manufacturers maintain productivity without compromising moisture control quality. Technical collaborations between suppliers and packaging engineers optimize canister placement, reducing manual handling and increasing line efficiency.

Performance Monitoring and Validation

Continuous validation of adsorption efficiency is critical for global shipments. Molecular sieve unit packs provide measurable performance indicators to verify moisture control.

- Laboratory-tested adsorption rates for varying RH conditions

- Saturation monitoring through periodic quality checks

- Data-supported assurance of shelf life consistency

Monitoring protocols include gravimetric testing, RH probes within shipping containers, and periodic sampling of packaged products. Documentation from these tests ensures traceable performance, reinforcing confidence in regulatory submissions and global logistics reliability.

Pharmaceutical Global Distribution

A leading pharmaceutical manufacturer recently integrated molecular sieve unit packs in their solid oral dosage shipments to multiple continents. Accelerated and real-time stability testing demonstrated that containers equipped with unit paks consistently maintained relative humidity below 5% RH over six weeks, preventing API degradation and extending shelf life.

That molecular sieve unit paks provide superior moisture control compared to standard silica gel desiccants, particularly in tropical and high-humidity environments. This highlights the importance of optimized desiccant placement and validated adsorption performance in maintaining product quality across global supply chains.

In Closing:

Selecting a reliable supplier ensures consistent quality and technical support. At Adsorbtek Solutions Inc., our molecular sieve unit packs are engineered for optimal performance in pharmaceutical, nutraceutical, and sensitive industrial applications. Our solutions provide precise moisture control while maintaining compliance with global standards. By choosing our molecular sieve pillow pak, clients receive a validated moisture control solution that enhances product longevity, supports automated packaging, and ensures safe distribution across global markets.

Contact Adsorbtek Solutions Inc. today to integrate high-performance molecular sieve unit paks into your supply chain and maintain shelf life consistency worldwide.

FAQs:

1.What is a molecular sieve unit pack used for?

It absorbs moisture in pharmaceutical and sensitive products, maintaining stability during storage and transit.

2. How does it improve shelf life across global distribution?

Controlling internal humidity prevents degradation and hydrolysis of moisture-sensitive formulations.

3. Can molecular sieve unit packs work in extreme conditions?

Yes, they maintain adsorption efficiency in high humidity and varying temperature conditions worldwide.

4. Are these unit paks compliant with regulatory standards?

Yes, they meet FDA, EU, RoHS, and GMP requirements for pharmaceutical applications.

5. Can molecular sieve unit packs integrate with automated packaging lines?

Yes, they are engineered for uniform size and stability, compatible with high-speed automated systems.