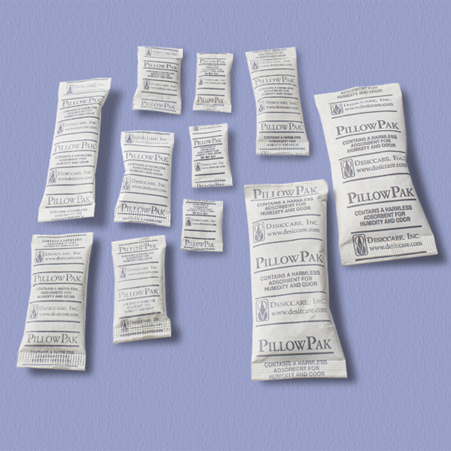

How Does Molecular Sieve Pillow Pak Support Long-Term Drug Storage Requirements?

Maintaining the stability of moisture-sensitive pharmaceuticals during storage and transport is critical for efficacy and regulatory compliance. Molecular sieve pillow pak plays a crucial role in safeguarding drugs by controlling relative humidity, preventing hydrolysis, crystallization, and potency loss. Engineered with precise desiccant compounds and barrier materials, these pillow paks are tailored for high-value pharmaceuticals that demand stringent storage conditions. Their consistent performance across various storage scenarios ensures both product integrity and regulatory adherence.

Critical Desiccant Compounds in Pillow Paks

The effectiveness of a molecular sieve pillow pak depends on the desiccant chemistry:

- Type 3A and 4A molecular sieves: Highly selective for water molecules, providing robust protection for moisture-sensitive APIs. Their crystalline structure allows for rapid adsorption of moisture even in high-humidity conditions.

- Activated alumina: Adds complementary adsorption capacity and is compatible with neutral pH-sensitive formulations, preventing chemical interactions.

- Silica gel composites: Integrated for dual-phase adsorption, enhancing overall performance in variable environmental conditions and extending operational life of the desiccant.

- Barrier laminates and films: Medical-grade, multi-layer laminates create a vapor-impermeable seal, ensuring moisture does not infiltrate during long-term storage or transit.

By combining these compounds strategically, pillow paks maintain a controlled microenvironment, preventing degradation pathways in both solid and liquid dosage forms.

Optimized Design for Uniform Moisture Control

Design precision determines how effectively pillow paks protect pharmaceuticals:

- Even desiccant distribution prevents localized moisture pockets that can compromise stability.

- Shape and surface area optimization maximizes adsorption efficiency across container surfaces, ensuring uniform moisture capture.

- Sealing integrity with high-barrier laminates ensures consistent performance over multi-month storage cycles, reducing the need for frequent monitoring.

Extended design considerations also include layered pouches and venting structures to accommodate high-volume shipments while maintaining uniform humidity protection throughout the pallet or container.

Compliance with Pharmaceutical Standards

Molecular sieve pillow paks must meet rigorous pharma guidelines to be viable:

- GMP-aligned production: Guarantees consistent moisture adsorption capacity across batches.

- FDA packaging requirements: Ensure moisture thresholds are met and materials are inert with APIs.

- ICH Q1A/B stability testing: Confirms drugs retain potency and stability over long-term storage, including under accelerated conditions.

- Pharma-grade validation: Confirms all desiccant compounds, barrier materials, and packaging films are compatible with regulatory expectations and do not introduce contaminants.

Meeting these standards reduces regulatory risks, ensures batch-to-batch reliability, and aligns with global storage requirements for high-value pharmaceuticals.

Advantages for Long-Term Drug Storage

Using molecular sieve pillow paks provides measurable benefits for pharmaceutical storage:

- Extended shelf life: Protects against hydrolysis, crystallization, and potency loss.

- Maintained drug efficacy: Ensures APIs remain therapeutically active throughout their intended shelf life.

- Streamlined logistics: Reduces sensitivity to external humidity and temperature fluctuations, enabling flexible storage options.

- Scalable applications: Suitable for bulk shipments, multi-pallet transport, and multi-container storage without compromising performance.

These advantages are critical for manufacturers handling high-value biologics, vaccines, or temperature-sensitive solid and liquid formulations, where every unit’s integrity is paramount.

Verification and Monitoring of Desiccant Performance

Continuous monitoring ensures pillow pak efficiency over storage and transit periods:

- Humidity indicator cards: Provide visual confirmation of moisture ingress inside containers.

- Adsorption testing: Confirms the desiccant is performing within expected operational parameters.

- Sealing checks: Validate barrier integrity across multi-layer laminate films.

- Compatibility tests with APIs: Ensure no chemical interactions occur, protecting both potency and stability.

These measures support quality assurance programs and align with global regulatory expectations, ensuring that each pharmaceutical batch maintains its safety profile.

Selection Criteria for Pharmaceutical Applications

Choosing the correct pillow pak involves a detailed evaluation of multiple factors:

- Desiccant type and quantity: Must match moisture sensitivity of the specific drug formulation.

- Container material and dimensions: Influence adsorption efficiency and overall humidity control.

- Storage duration and environmental conditions: Determine the required desiccant load and barrier specifications.

- Regulatory compliance: Must meet GMP, FDA, and ICH standards to avoid storage-related quality failures.

Proper selection ensures optimal performance, minimizes degradation risk, and supports predictable shelf-life performance, even in complex distribution chains.

Integration Into Supply Chains

Molecular sieve pillow paks are designed for seamless integration into pharmaceutical packaging and logistics systems:

- Automated filling compatibility: Reduces handling errors and contamination risk during packaging.

- Predictable adsorption rates: Maintain consistent quality across shipments and batches.

- Multi-format adaptability: Compatible with bottles, cartons, and palletized shipments, enabling operational flexibility.

- Reduced operational intervention: Maintains regulatory compliance without additional monitoring or adjustments during transport.

These factors enable manufacturers to ensure product integrity while optimizing efficiency across the supply chain.

Final Note:

At Adsorbtek Solutions Inc., our molecular sieve pillow pak solutions are engineered for pharmaceuticals that require reliable long-term storage and regulatory compliance. By combining precise desiccant compounds like 3A and 4A molecular sieves, activated alumina, and silica gel composites with robust multi-layer barrier laminates, we ensure drug stability, prevent moisture ingress, and maintain controlled relative humidity. Our expertise extends to seamless integration into packaging lines and supply chain operations. Partner with us for advanced polyester coil desiccant packaging solutions designed to protect your products and preserve their quality throughout storage and transport.

Secure your moisture-sensitive pharmaceuticals with Adsorbtek Solutions Inc. today. Enhance long-term storage performance and regulatory compliance with our molecular sieve pillow pak solutions.

FAQs:

Q1: What is a molecular sieve pillow pak?

A molecular sieve pillow pak is a pharma-grade desiccant pouch designed to control humidity and protect moisture-sensitive drugs during storage and transport.

Q2: How does it support long-term drug storage?

It maintains a controlled microenvironment by adsorbing moisture, preventing hydrolysis, crystallization, and potency loss in pharmaceuticals.

Q3: What compounds are used in these pillow paks?

Common compounds include 3A/4A molecular sieves, activated alumina, and silica gel composites, combined with multi-layer barrier laminates.

Q4: Are molecular sieve pillow paks compliant with regulations?

Yes, they are manufactured according to GMP, FDA, and ICH guidelines, ensuring consistent performance and regulatory adherence.

Q5: How are pillow paks integrated into pharmaceutical packaging?

They can be incorporated into bottles, cartons, pallets, or containers, providing uniform humidity control throughout the supply chain.