How Does Cargo Desiccant Packaging Protect Against Seasonal Humidity Changes?

Maintaining product integrity during transit is crucial, and cargo desiccant packaging plays a vital role in shielding shipments from fluctuating humidity. Seasonal changes can cause moisture variations that compromise product quality, making effective moisture control essential for sensitive goods. Properly designed desiccant packaging adapts to a wide range of environmental conditions, offering a reliable solution for global shipping needs.

Understanding Seasonal Humidity Challenges

- Humidity spikes: High moisture levels during rainy or humid seasons can accelerate corrosion, mold growth, and product degradation.

- Low humidity impacts: Dry seasons can cause packaging shrinkage or material brittleness, leading to potential leaks or contamination.

- Temperature fluctuations: Changes in temperature amplify humidity effects, stressing conventional packaging systems.

By understanding these challenges, businesses can deploy targeted moisture control strategies that maintain product quality throughout transit. Seasonal variations are often unpredictable, and even short-term exposure to high or low humidity can compromise product safety. For sensitive shipments, recognizing these risks is the first step toward robust moisture management.

Mechanism of Cargo Desiccant Packaging

- Moisture adsorption: Desiccants absorb excess moisture inside containers, preventing condensation and damp conditions.

- Humidity stabilization: They maintain an optimal internal environment, protecting products from seasonal swings in moisture.

- Material compatibility: Desiccants are engineered to work with various cargo types, including pharmaceuticals, electronics, and food items.

The absorption process involves a chemical or physical reaction between the desiccant material and water molecules, ensuring consistent humidity control. This mechanism ensures sensitive goods are transported safely, reducing risks associated with seasonal humidity fluctuations. In addition, the right packaging design complements desiccant efficiency, helping to maximize moisture protection across the entire shipment.

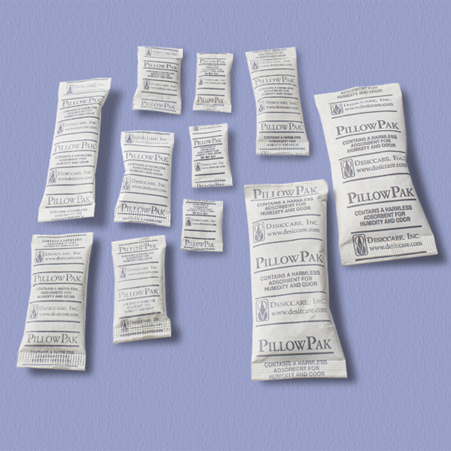

Types of Desiccants Used in Cargo Packaging

- Silica gel: Highly effective for general moisture absorption, suitable for most shipping conditions.

- Clay-based desiccants: Ideal for moderate moisture control in bulk shipments.

- Molecular sieves: Specialized for extreme humidity conditions, offering consistent performance under challenging climates.

- Activated carbon blends: Provide dual protection by adsorbing moisture and reducing odors or chemical vapors.

Selecting the correct desiccant type based on shipment requirements ensures consistent performance and product protection. Different desiccants have unique moisture adsorption rates and capacities, making it important to consider factors like container size, transit duration, and seasonal conditions. Using multiple desiccant types together can also enhance protection, creating a layered defense against moisture.

Testing and Compliance Standards

- Moisture Vapor Transmission Rate (WVTR) tests: Evaluate packaging efficiency in blocking moisture penetration.

- Container integrity tests: Ensure seals and packaging materials withstand seasonal stress.

- Regulatory compliance: Packaging meets standards such as U.S. FDA, EU Food Safety, and international shipping guidelines.

Regular testing guarantees that desiccants and packaging perform effectively under varying seasonal conditions. It also helps businesses monitor desiccant performance over time, making adjustments for shipments exposed to extreme humidity or long transit periods. Compliance with global standards ensures that cargo meets regulatory expectations and minimizes the risk of product recalls.

Benefits of Effective Cargo Desiccant Packaging

- Preserved product quality: Prevents moisture-induced damage, ensuring shipments arrive intact.

- Reduced returns and losses: Minimizes spoilage or rejection due to humidity-related issues.

- Extended shelf life: Maintains stability for sensitive products such as biologics, nutraceuticals, and electronics.

- Operational efficiency: Reduces the need for emergency interventions or repackaging during transit.

These benefits make cargo desiccant packaging a critical investment for businesses managing seasonal shipments. Companies that use advanced desiccant solutions can maintain customer satisfaction and reduce operational costs caused by moisture-related damages.

Best Practices for Seasonal Shipping

- Optimal desiccant placement: Positioning desiccants near moisture-sensitive areas enhances protection.

- Container monitoring: Use data loggers to track humidity changes and desiccant performance in transit.

- Pre-conditioning shipments: Adjust packaging environment to reduce exposure to extreme seasonal moisture changes.

- Proper storage before shipping: Maintain containers in controlled conditions to maximize desiccant efficiency.

Following these practices ensures maximum protection from seasonal humidity effects. Proper planning also helps anticipate environmental changes during transit, allowing businesses to choose the most suitable desiccant type and quantity for each shipment.

Ending Note:

Our cargo dry plus packaging solutions are designed to adapt to seasonal variations, offering reliable moisture control across global supply chains. At Adsorbtek Solutions Inc., our focus is on providing packaging systems that maintain product integrity, extend shelf life, and protect against environmental fluctuations. With customized cargo desiccant packaging, businesses can manage seasonal humidity effectively, ensuring consistent product quality while reducing losses and compliance risks.

Strengthen your shipments against seasonal humidity. Contact Adsorbtek Solutions Inc. for tailored cargo desiccant packaging solutions today.

FAQs:

What is cargo desiccant packaging?

Cargo desiccant packaging uses moisture-absorbing materials to maintain stable humidity, protecting sensitive goods during transit.

How does it protect products from seasonal humidity?

Desiccants absorb excess moisture and stabilize internal conditions, preventing spoilage or damage during fluctuating humidity.

Which industries benefit most from desiccant packaging?

Pharmaceuticals, nutraceuticals, electronics, and food shipments benefit, as they are highly sensitive to moisture changes.

What types of desiccants are commonly used?

Silica gel, clay-based desiccants, molecular sieves, and activated carbon blends provide different levels of moisture control.

How can I monitor desiccant effectiveness during transit?

Humidity data loggers and container testing help track performance, ensuring products remain protected throughout shipping.