Why Are Molecular Sieve Unit Paks Critical in High-Value Pharma Exports?

Studies report that the global molecular sieve desiccants market was valued at about USD 3.68 billion in 2024, driven strongly by pharmaceutical demand for precise moisture control. Pharmaceutical shipments with moisture-sensitive formulations require exacting protection. A molecular sieve unit pak provides ultra-low relative humidity environments that suppress hydrolysis, oxidation, and microbial growth. These packs are engineered to meet GMP packaging compliance under FDA and EMA guidelines. For high-value exports of biologics, peptides, or sterile creams, molecular sieve systems are not optional but essential for maintaining API potency and product safety during transport.

Controlled Adsorption Performance in Pharma Packaging

Molecular sieves outperform traditional desiccants due to their crystalline pore structure. By selectively adsorbing water molecules at very low relative humidity levels, they maintain conditions below 10% RH inside packaging.

Performance studies have demonstrated that molecular sieves can reduce moisture uptake by 40% compared with silica gel under accelerated stability conditions. This consistency makes them suitable for antibiotics, peptides, effervescent formulations, and other APIs where hydrolysis risk is high.

Unlike bulk silica or clay-based desiccants, molecular sieves maintain adsorption efficiency even at elevated temperatures. This characteristic is particularly important during long-distance transport through tropical or high-humidity regions, where standard desiccants can lose effectiveness. For products requiring strict shelf-life stability, molecular sieves create a controlled environment that significantly lowers out-of-specification risks.

GMP Relevance in Export Packaging Systems

Good Manufacturing Practice (GMP) requirements extend beyond drug formulation into packaging integrity. For desiccant integration, compliance includes:

- Cleanroom-grade production of unit paks to minimize particulate risk.

- Complete batch traceability from raw molecular sieve material to finished product.

- Validated adsorption profiles documented in ICH stability studies.

- Compatibility testing with APIs and excipients to ensure no extractables or leachables.

These measures reduce the possibility of deviations during audits and inspections. With international regulators focusing on packaging as part of product quality, the use of compliant desiccants has become a critical step for global exports. GMP alignment demonstrates that the entire packaging system, not just the drug substance, has been designed with product safety and compliance in mind.

Addressing Hydrolysis in High-Value APIs

Hydrolysis is a major degradation pathway for sensitive molecules. Even trace levels of moisture can destabilize proteins, nucleotides, and small molecules, reducing potency and bioavailability. Molecular sieves adsorb water vapor to below detectable levels, effectively suppressing hydrolytic breakdown.

Export data on monoclonal antibody vials showed that shipments packaged with molecular sieve desiccants retained stability for 12 months longer compared with controls lacking sorbents. This performance reinforces their role in safeguarding multimillion-dollar exports.

For injectable therapies and biologics, where cold-chain logistics already pose challenges, desiccant systems create a second layer of protection. The stability gained during extended transport not only improves patient safety but also reduces financial losses from rejected batches at receiving facilities.

Integration into Export Logistics

Pharmaceutical exporters require solutions that integrate seamlessly into operational workflows. Molecular sieve unit paks are compact, dust-free, and FDA-cleared for indirect product contact, making them suitable for secondary and tertiary packaging.

Key operational benefits include:

- Space-efficient design that does not reduce shipment payload.

- Low-dust construction prevents contamination during handling.

- Performance validated across ICH climate zones I–IV, ensuring global reliability.

Unit paks can be used across multiple container types, including blister cartons, bulk drums, and sealed shipping crates. Their lightweight format ensures minimal impact on freight costs while still delivering robust protection. By reducing variability across different export routes and climates, molecular sieves simplify logistics planning for pharma companies shipping to multiple global markets.

Alignment with Global Regulatory Frameworks

Both the FDA and EMA emphasize packaging systems that preserve stability during transit. Molecular sieve desiccants, supported by validation data, form part of the container-closure system documentation required for regulatory approval.

Supporting data typically includes adsorption isotherms, accelerated aging studies, and compliance with USP <671> for packaging performance. Their established acceptance in regulatory submissions positions them as trusted components in pharma exports.

For exporters targeting multiple jurisdictions, using molecular sieve unit paks reduces the burden of revalidating packaging systems for each region. Their acceptance in regulatory filings accelerates market release timelines and strengthens confidence during inspections.

In The End:

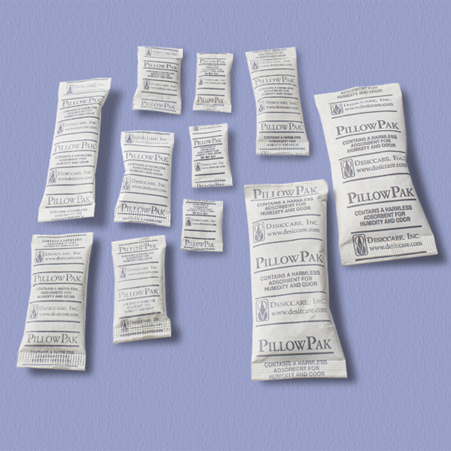

High-value pharmaceuticals require packaging systems that eliminate degradation risks. Molecular sieves, with validated moisture adsorption, GMP-oriented production, and regulatory acceptance, deliver this assurance. Beyond bulk shipments, the same performance extends to smaller pack sizes, such as the molecular sieve pillow pak in the USA, designed for use in cartons and vials. At Adsorbtek Solutions Inc., we engineer molecular sieve desiccant solutions that align with GMP and international export standards. Our expertise ensures reliable protection of pharmaceutical products against hydrolysis, oxidation, and transit-related instability.

Contact us today to explore how our molecular sieve solutions can secure your high-value pharmaceutical exports.

FAQs:

Q1. What makes molecular sieve unit paks suitable for pharma exports?

They maintain ultra-low humidity, protect APIs from hydrolysis, and meet GMP packaging requirements.

Q2. How do molecular sieves differ from silica gel in pharma packaging?

Molecular sieves adsorb moisture at lower relative humidity levels, making them more reliable for sensitive APIs.

Q3. Can molecular sieve unit paks be used in cold chain logistics?

Yes, they remain effective at low temperatures and complement cold storage by controlling micro-level moisture.

Q4. Do molecular sieve desiccants meet global regulatory requirements?

Yes, they comply with FDA, EMA, and USP standards for pharmaceutical packaging and stability.

Q5. Where are molecular sieve unit paks applied in pharma exports?

They are used in blister cartons, vials, bulk drums, and sealed shipping containers.