How Activated Carbon Desiccant Packaging Safeguards Moisture-Sensitive Goods

Moisture intrusion is one of the most common and underestimated threats to product stability. For industries handling pharmaceuticals, medical kits, and lab-based goods, the stakes are even higher. Even the slightest exposure to humidity can compromise efficacy, shelf life, and safety. This is where activated carbon desiccant packaging steps in as a critical barrier against contamination and product degradation.

Why Moisture Control Isn't Optional for Sensitive Goods

Moisture-sensitive items are more vulnerable than most packaged goods. Their composition—be it chemical, organic, or biological can change with minimal environmental influence. Capsules can harden, pills can crumble, and medical components can lose function. In closed packaging environments, any failure in moisture regulation leads to irreversible damage, recalls, and reputation risks.

Industries that rely on consistent air quality throughout storage and transit need solutions that not only absorb moisture but also neutralize unwanted odors and airborne pollutants. Activated carbon-based solutions fill this role efficiently.

How Activated Carbon Desiccant Outperforms Traditional Options

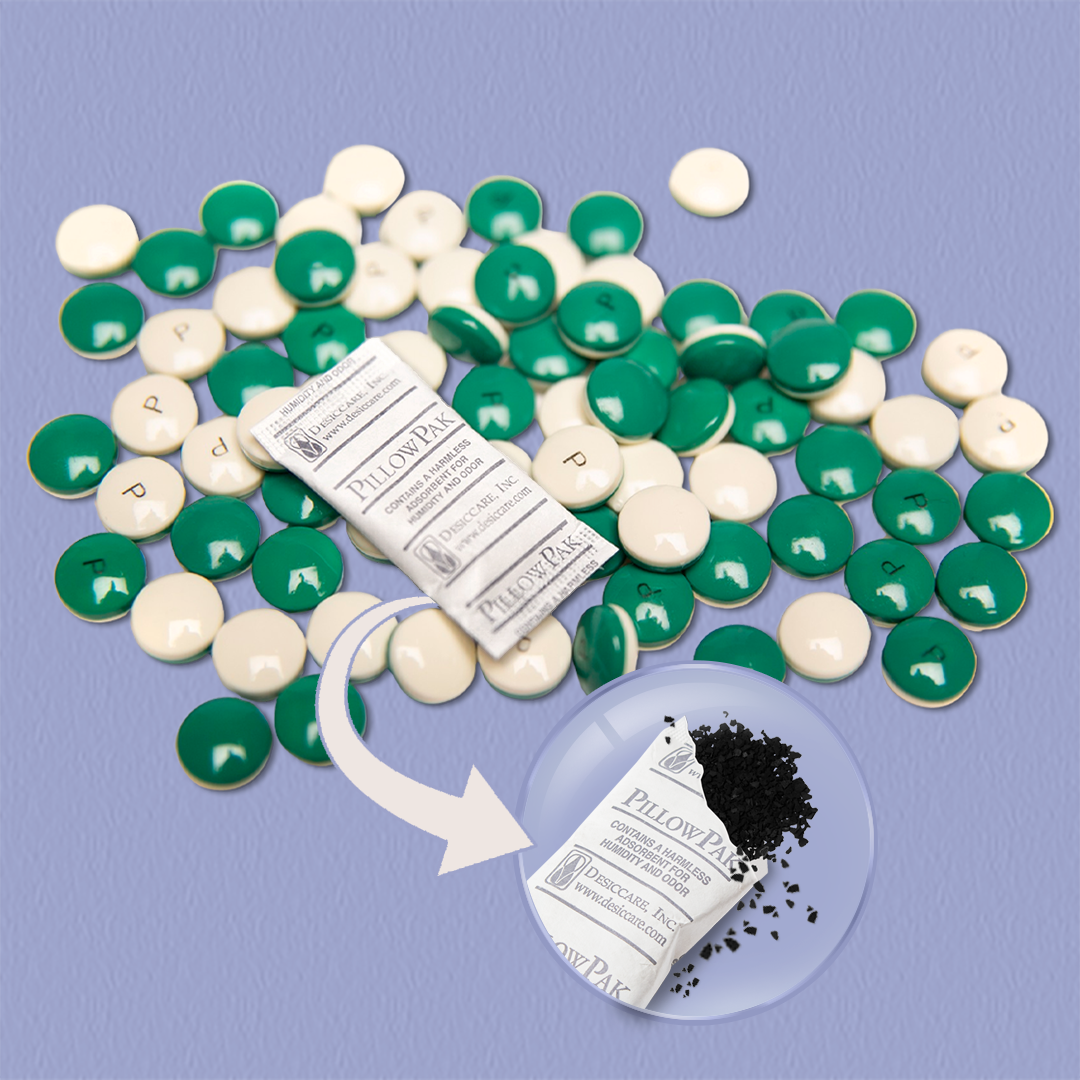

What sets this form of packaging apart is its dual-action capacity. While standard desiccants absorb moisture, activated carbon desiccant traps odors and volatile organic compounds (VOCs) alongside humidity. This creates a purified atmosphere within packaging, maintaining stability across long hauls and changing climates.

The fine porous structure of activated carbon provides a high surface area that captures contaminants at the molecular level. Its ability to adsorb stubborn gases and moisture makes it ideal for high-stakes applications, where one breach in integrity can cost thousands.

Built for Consistency from Production Line to Delivery

In high-volume manufacturing settings, maintaining consistency is key. Products like capsules and tablets are mass-produced, then stored and shipped globally. Throughout this process, they face fluctuating temperatures, uncontrolled environments, and prolonged packaging times.

Activated carbon desiccant packaging provides stability by continuously regulating the microclimate inside each container. Whether it’s a short supply chain or international distribution, this packaging ensures goods arrive in the same state they left the facility—untouched by moisture or odor.

Enhancing Product Integrity in the Medical and Pharma Sector

Medical test kits, diagnostics, nutraceuticals, and medical devices require packaging that goes beyond basic protection. The stakes are higher, and regulatory standards are stricter. Activated carbon offers a tested and compliant solution. It holds certifications from the U.S. FDA, EU authorities, and U.S. Pharmacopeia standards, making it suitable for use in regulated applications.

The material itself—non-toxic, fragrance-free, and stable, adds no contamination risk. It acts quietly but efficiently in the background, protecting both the product and the end user’s safety.

Packaging Features That Add Real-World Value

The outer shell of activated carbon desiccants is designed for toughness and breathability. From tear-resistant fabrics like Tyvek to anti-dust coatings and food-grade inks, every element is engineered for real-world logistics and storage. High vapor transmission rates and strong seals further enhance reliability. These features prevent leakage, breakage, and material deterioration—even during extended storage.

This makes activated carbon packaging ideal not just for shelf life, but also for compliance and brand reputation.

Prevents Cross-Contamination in Mixed Packaging Environments

In packaging setups where multiple components or materials are stored together, cross-contamination is a serious risk. Moisture can act as a carrier for odor or compound transfer between items, especially in tightly packed conditions. Activated carbon desiccant packaging eliminates this issue by locking in contaminants before they can interact with adjacent materials. This is particularly critical in kits that contain both organic and chemical elements, where maintaining isolation is essential.

Supports Long-Term Shelf Stability Without Active Cooling

Many pharmaceutical and diagnostic products require consistent conditions during storage, but active refrigeration is not always feasible—especially during transport. Activated carbon-based packaging maintains product safety without the need for energy-dependent systems. By stabilizing humidity and air composition within the sealed environment, it extends shelf life even under room-temperature storage, offering cost savings and logistics flexibility.

Closing Note:

Activated carbon pillow pak technology goes beyond simple desiccation. It controls air quality, reduces spoilage, and provides compliance-ready assurance for sensitive goods. For any business focused on product stability especially those in pharmaceuticals, diagnostics, or nutraceuticals this solution stands as a vital upgrade in packaging science. At Adsorbtek Solutions Inc., our activated carbon pillow pak is tailored for real-world challenges. Built for consistency, tested for safety, and trusted across industries, our paks deliver performance where it counts. With various sizes and strip formats available, we meet every packaging need with flexibility and precision.

Secure the integrity of your sensitive goods with Adsorbtek Solutions Inc., connect with our packaging specialists today to ensure product safety from production floor to final destination.