How Does Bulk Desiccant for Shipping Help Maintain Quality During Delivery?

Every year, companies lose millions due to moisture damage during transit. From rusted machinery to spoiled food, hidden humidity quietly erodes the value of their cargo. One simple yet highly effective solution is the use of bulk desiccant for shipping. These moisture-absorbing materials are widely used across many industries to protect goods from humidity-related problems during transportation.

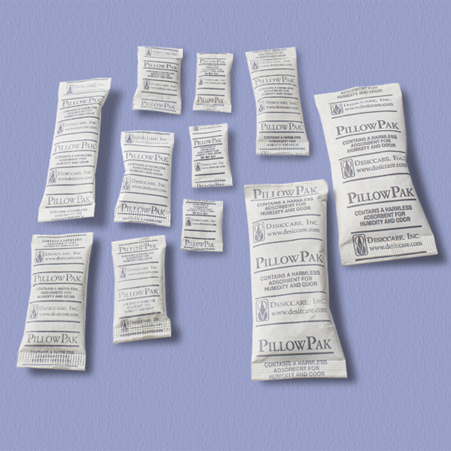

Choosing the Right Desiccant Packaging Materials for Shipping

Freight containers, trucks, and storage units frequently experience temperature fluctuations. These changes trigger condensation, especially in closed spaces. When this happens, moisture collects on surfaces or seeps into packaging. As a result, items inside may become damp, leading to:

- Rust on metal parts

- Mold growth

- Damage to packaging

- Product spoilage

- Shortened shelf life for sensitive goods

- Discoloration of materials like leather

- Malfunction or short-circuiting of electronics

Some items are sensitive to moisture. For example, electronics can short-circuit, leather can discolor, and food items may spoil quickly. These problems not only affect the product but can also lead to returns, financial losses, and customer complaints. This is why keeping cargo dry during transit is so important.

Understanding the Role of Desiccants in Logistics

Desiccants are materials that pull in and hold moisture from the surrounding air. When used in bulk for shipping, they create a dry space inside packages or cargo containers. This keeps humidity low and protects goods from rust, mold, and weakening of boxes or wrapping.

There are several kinds of desiccants used in shipping. Silica gel, clay, and calcium chloride are some common ones. Each has different strengths depending on how much moisture it can hold and how long it lasts. Some are better for closed packages, while others work well for full shipping containers.

Using the right type of desiccant helps companies maintain product quality, reduce shipping-related damage, and avoid customer dissatisfaction.

Ideal Cargo Types That Benefit from Moisture Protection

Some products are more likely to get damaged by moisture than others. Using desiccants helps protect items such as:

- Metal parts and tools: Can rust or corrode if exposed to moisture

- Leather items: May stain or lose shape if damp

- Medicines and health products: Require controlled humidity to remain effective

- Electronics: Water vapor can damage internal parts and cause failure

- Clothing and textiles: Can grow mildew or develop unpleasant smells

By using bulk desiccants, businesses protect these items during shipping. This keeps the product safe and helps maintain the company’s reputation for quality.

Choosing the Right Quantity and Placement

To get the most from desiccants, it’s important to use the correct amount and place them properly. Too little won’t provide enough protection, while too much can increase costs.

Factors influencing how much desiccant is needed include shipment size, transit duration, type of cargo, and how well the container is sealed. Placement is also key. Desiccants should be spread inside the container or placed near areas most likely to collect moisture.

Some desiccants can be hung inside containers, while others are placed directly inside boxes. Choosing the right setup improves efficiency and reduces the risk of damage.

Benefits Beyond Product Preservation

Moisture control does more than protect products. It also improves the overall shipping experience. When items arrive dry and undamaged, customers are more likely to be satisfied and return for future purchases.

Shipping delays and complaints cost businesses time and money. Moisture damage often means products must be replaced or refunded. Using desiccants reduces these issues and increases delivery success rates.

In large-scale operations, this can significantly impact profit margins. A small step like adding desiccants helps avoid bigger problems later.

How Bulk Solutions Improve Efficiency

For companies handling large shipments, bulk desiccants simplify the process. Instead of placing many small packets, a few large units can do the job. This saves time and keeps the packaging process organized.

It also lowers the risk of loose packets spilling or getting lost. In large warehouses, this efficiency helps workers move faster, reduces errors, and keeps the packaging line smooth.

Bulk desiccants are also easy to store and manage. They take up less space than thousands of smaller packets and are quicker to deploy during packaging.

Closing Note:

At Adsorbtek Solutions Inc., we help you protect what matters most. Our advanced desiccant packaging materials in USA are designed for real shipping conditions. Whether your goods are crossing states or oceans, our moisture-control solutions help reduce spoilage and keep your shipments safe.

Our team works with you to understand your shipping needs. We then recommend the right product and setup for your cargo. Whether you need protection for metal tools, electronics, food items, or sensitive devices, we have moisture-control options that meet those demands.

Every shipment matters, and we support your business with tested, reliable products and deep industry knowledge. Our goal is to help you lower losses, improve customer satisfaction, and strengthen your delivery process.

FAQs:

1. What is a bulk desiccant for shipping?

Bulk desiccants are materials that absorb moisture to keep products dry during transit.

2. Why is moisture control important in shipping?

It prevents damage like rust, mold, and spoilage, ensuring products arrive in good condition.

3. Which products need desiccants during delivery?

Electronics, textiles, leather, metals, and medicines often require moisture protection during transport.

4. How much desiccant should I use in a shipment?

The right amount depends on cargo type, packaging size, and expected transit time.

5. Where should desiccants be placed in packaging?

They should be spread evenly or placed near moisture-sensitive areas for best results.