Why Compliance-Driven Brands Partner With Proven Pharma Desiccant Suppliers

Maintaining moisture control in pharmaceutical products is not optional; it’s a compliance requirement. Pharma desiccant suppliers provide engineered solutions that prevent hydrolysis, oxidation, and microbial growth in sensitive drugs, ensuring active pharmaceutical ingredients (APIs) retain their stability throughout production, storage, and distribution. Effective moisture control safeguards product integrity, reduces recall risks, and ensures compliance with FDA and GMP guidelines. Additionally, these solutions streamline supply chains by mitigating risks associated with high-value or temperature-sensitive shipments.

Moisture Threats in High-Value Pharma Products

Even minor humidity variations can trigger chemical and physical degradation in drugs. Moisture risks include:

- Hydrolysis of APIs: Certain APIs, such as ampicillin and ceftriaxone, degrade rapidly when exposed to excess water, reducing potency.

- Excipient Instability: Lactose, starch, and other moisture-sensitive excipients can clump or dissolve unevenly, affecting dosage uniformity and formulation consistency.

- Packaging Weakness: Laminated tubes, blister packs, and high-barrier containers may fail if RH levels exceed recommended thresholds, impacting shelf life.

- Cross-Contamination Risk: Moisture can accelerate microbial growth in multi-drug storage, creating contamination hazards.

Pharma desiccants create a controlled microenvironment, maintaining stability across APIs and excipients, and complying with USP <671> and ICH Q1A stability standards.

Key Complexes Used in Pharma Desiccants

Pharmaceutical desiccants rely on precise chemical complexes for effective moisture absorption:

- Silica Gel: Provides high-capacity adsorption for both liquid and solid dosage forms, with color-indicating variants allowing visual monitoring of saturation levels.

- Molecular Sieves: Zeolite-based materials selectively adsorb water molecules, ideal for highly hygroscopic APIs and products requiring ultra-low moisture conditions.

- Calcium Oxide: Rapidly absorbs water in high-humidity environments, commonly paired with silica gel for multi-layer protection.

- Clay and Bentonite: Economical desiccants suitable for moderate moisture-sensitive products, commonly used in bulk packaging.

- Activated Carbon Additives: Remove residual moisture while controlling odors, particularly in multi-component formulations.

The correct combination of these complexes ensures tailored protection based on API sensitivity, storage conditions, and regulatory standards.

Compliance Essentials for Pharma Desiccant Applications

Brands rely on pharma desiccant suppliers to meet rigorous regulatory requirements:

- GMP Integration: Manufacturing, storage, and handling of desiccants must comply with ISO 9001 and WHO GMP protocols, ensuring process consistency.

- FDA Guidelines: Desiccants must be chemically inert, non-toxic, and validated to maintain moisture within defined limits.

- ICH Stability Testing: Validated performance across accelerated and long-term storage ensures desiccants consistently control relative humidity.

- Container Compatibility: Tubes, bottles, blister packs, and multi-pallet shipments must accommodate desiccants without compromising integrity or chemical stability.

Meeting these compliance essentials reduces the risk of regulatory action, product recalls, and financial loss.

Integrating Desiccants Into Packaging Lines

Efficient integration enhances desiccant performance and operational reliability:

- Automated Desiccant Insertion: Ensures consistent placement in multi-unit packaging, reducing human error and production downtime.

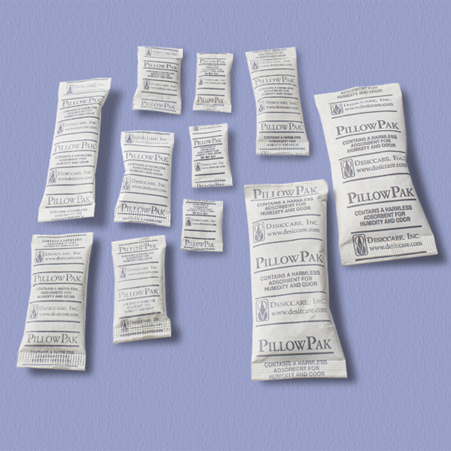

- Custom Unit Paks and Pillow Paks: Engineered to fit blister packs, bottles, and multi-pallet shipments, providing uniform moisture control across all units.

- Humidity Monitoring: Inline RH sensors enable real-time verification of environmental control, allowing proactive adjustments to desiccant placement or quantity.

- Layered Protection Strategies: Combining molecular sieve paks with silica gel canisters ensures redundancy, preventing moisture spikes even in complex packaging.

- Process Documentation: Maintaining validation logs for insertion, monitoring, and compliance supports audit readiness and regulatory traceability.

Operational Advantages of Trusted Suppliers

Partnering with experienced suppliers provides measurable business benefits:

- Reduced Product Loss: Proper moisture control prevents API degradation, batch rejection, and costly recalls.

- Regulatory Assurance: Solutions align with FDA, EMA, USP, and ICH guidelines, ensuring compliance in global markets.

- Scalable Solutions: Adaptable from small R&D batches to multi-pallet international shipments, facilitating supply chain flexibility.

- Technical Expertise: Suppliers provide guidance on chemical compatibility, packaging designs, and performance validation.

- Efficiency Gains: Optimized desiccant placement reduces material waste, labor costs, and potential downtime in production lines.

These advantages collectively strengthen product reliability, operational performance, and brand reputation.

Ending Note:

At Adsorbtek Solutions Inc., we deliver scientifically validated, regulation-ready solutions for moisture-sensitive pharmaceuticals. Our silica gel unit pak and molecular sieve designs are engineered to integrate seamlessly into production lines, meeting GMP, FDA, and ICH compliance requirements. From sensitive APIs to multi-pallet shipments, our desiccants maintain product integrity, extend shelf life, and enhance operational efficiency. Partner with us to implement tailored moisture-control strategies that protect your high-value pharmaceutical products while ensuring complete regulatory adherence.

Contact Adsorbtek Solutions Inc. to implement validated, compliance-driven pharma desiccant solutions today.

FAQs:

1. What are pharma desiccant suppliers?

Pharma desiccant suppliers provide engineered moisture-control solutions for pharmaceutical packaging to maintain product stability and compliance.

2. Why is moisture control critical in pharma products?

Moisture can degrade APIs, destabilize excipients, and reduce shelf life, affecting efficacy and regulatory compliance.

3. What types of desiccant complexes are used in pharmaceuticals?

Common complexes include silica gel, molecular sieves, activated carbon, calcium oxide, and bentonite, tailored to specific APIs.

4. How are desiccants integrated into packaging lines?

They are inserted as unit paks or pillow paks, with automated placement and humidity monitoring for consistent moisture control.

5. How do desiccant solutions support regulatory compliance?

They ensure stability under GMP, FDA, and ICH guidelines, supporting audits, documentation, and international shipment requirements.