How Can Pharmaceutical Packaging Solutions Reduce Contamination Risks

Pharmaceutical packaging solutions play a critical role in ensuring the safety and efficacy of medicines by minimizing exposure to contaminants. In the pharmaceutical industry, protecting formulations from moisture, dust, microbes, and chemical interference is essential. Advanced packaging methods create a controlled barrier, maintaining product stability from manufacturing through delivery. Proper packaging reduces spoilage, preserves potency, and guarantees patient safety, making it a fundamental part of pharmaceutical supply chains.

Ensuring Hygienic Packaging Environments

Maintaining a sterile environment during packaging is vital for contamination control. Controlled humidity, filtered air, and cleanroom practices prevent microbial and particulate intrusion. Using high-quality pharmaceutical packaging materials ensures that external elements cannot penetrate, safeguarding sensitive tablets, capsules, injectables, and powders.

- Employing cleanroom-approved packaging materials minimizes dust and microbial contamination.

- Sealing mechanisms prevent air and particle ingress, maintaining formulation integrity.

- Incorporating microbial-resistant coatings provides additional protection for moisture-sensitive drugs.

Routine monitoring of cleanroom environments and strict adherence to GMP standards ensure that pharmaceutical products are packaged under conditions that reduce the risk of contamination at every stage.

Barrier Properties and Material Selection

Packaging materials with superior barrier properties are essential to prevent contamination. Multi-layer laminates, high-density plastics, and aluminum foils effectively block moisture, oxygen, and light, which can compromise drug stability. Selecting the correct material based on formulation type ensures longer shelf life and minimizes degradation risks.

- Aluminum and laminated barriers protect light-sensitive and hygroscopic compounds.

- Plastic containers with low permeability safeguard formulations prone to moisture absorption.

- Combination materials, such as foil-plastic laminates, provide maximum chemical and physical protection.

Choosing the right material depends on the type of pharmaceutical product, its shelf-life requirements, and storage conditions, ensuring consistent performance from packaging to patient delivery.

Tamper-Evident Features for Safety

Incorporating tamper-evident elements is critical for preventing contamination and ensuring integrity during handling and transit. Seals, caps, and closures designed to show evidence of interference provide assurance that the medication remains untouched and uncontaminated until use.

- Breakable seals on bottles and vials clearly indicate any unauthorized opening.

- Shrink bands add an additional visible layer of protection.

- Visible indicators on closures alert consumers to tampering, ensuring confidence and safety.

Tamper-evident features also support regulatory compliance, meeting requirements for safe pharmaceutical packaging while protecting brand integrity and patient trust.

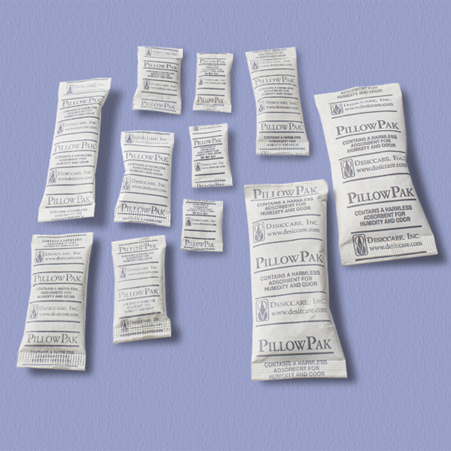

Controlled Atmosphere and Moisture Management

Pharmaceutical packaging solutions often integrate moisture and oxygen control systems to maintain product stability. Desiccants, oxygen absorbers, and vacuum-sealed containers protect formulations from environmental factors. These measures prevent microbial growth, chemical reactions, and physical changes that could compromise product safety.

- Silica gel and molecular sieve canisters manage humidity inside containers.

- Oxygen scavengers prevent oxidation in highly sensitive formulations.

- Vacuum-sealed and inert gas-flushed packaging reduces the chance of contamination during shipping and storage.

These systems are especially critical for biologics, nutraceuticals, and moisture-sensitive medications, where even minor exposure can alter potency or cause degradation.

Rigorous Testing and Compliance

Regular testing ensures that packaging solutions meet contamination prevention standards. Barrier integrity, mechanical strength, and microbial resistance are evaluated to guarantee compliance with regulatory requirements. Adherence to FDA, USP, and EU guidelines provides assurance that packaging maintains safety during storage and distribution.

- Leak and burst testing confirms container integrity under stress.

- Microbial challenge tests validate the effectiveness of barrier and closure systems.

- Compliance with U.S. FDA 21 CFR, USP <671>, and EU regulations ensures global standards are met.

By conducting these tests routinely, manufacturers can identify potential vulnerabilities in packaging design and make necessary improvements to reduce contamination risks.

Logistics and Transportation Considerations

Pharmaceutical products are exposed to varying environmental conditions during transit. Advanced packaging solutions mitigate contamination risks by maintaining controlled internal conditions. Properly designed shipping containers and desiccant systems ensure that medications remain stable across global distribution channels.

- Shock-absorbing designs prevent physical damage to containers during handling.

- Temperature-stable packaging maintains efficacy for thermosensitive formulations.

- Desiccant integration protects moisture-sensitive drugs from humidity variations in shipping environments.

Monitoring and selecting packaging solutions tailored to specific transit requirements is crucial for preserving drug quality and preventing contamination before reaching healthcare providers and patients.

Enhancing Shelf Life and Product Quality

Effective pharmaceutical packaging solutions directly enhance shelf life and maintain product quality. By controlling environmental exposure, preventing microbial contamination, and protecting against physical damage, medicines retain their intended potency and safety profile throughout their lifecycle.

- Optimized barrier selection ensures maximum protection for each formulation.

- Desiccant integration reduces the risk of degradation in moisture-sensitive drugs.

- Tamper-proof features maintain product safety and regulatory compliance.

Maintaining consistent performance across storage and transport conditions ensures patients receive medications that meet the highest safety standards.

Closing Note:

At Adsorbtek Solutions Inc., our pharmaceutical packaging solutions are engineered to reduce contamination risks at every stage, from manufacturing to delivery. By combining advanced barrier technologies, tamper-evident systems, and controlled moisture management, we ensure the stability, safety, and compliance of your formulations. Our shipping desiccant packaging solutions provide reliable protection, enhancing product shelf life and maintaining quality across global distribution networks. Contact us today to optimize your pharmaceutical packaging strategies and safeguard your products.

FAQs:

1. What are pharmaceutical packaging solutions?

Pharmaceutical packaging solutions are materials and systems designed to protect medicines from contamination, moisture, and environmental damage during storage and transit.

2. How do packaging solutions prevent contamination?

They use barriers, tamper-evident seals, and controlled atmosphere systems to block microbes, moisture, and external pollutants.

3. Why is barrier integrity important in pharmaceutical packaging?

Barrier integrity ensures drugs remain stable and safe, preventing degradation or potency loss over their shelf life.

4. What role do desiccants play in packaging?

Desiccants manage moisture levels inside containers, protecting sensitive formulations from humidity-induced spoilage.

5. How does testing ensure packaging effectiveness?

Regular testing of seals, barrier strength, and microbial resistance verifies that packaging maintains safety and compliance standards.