How Pharmaceutical Packaging Solutions Help Improve Product Shelf Life

Every year, millions of dollars in medicines are lost due to weak packaging. Exposure to air, moisture, or light can reduce potency and shorten shelf life. Pharmaceutical packaging solutions from trusted suppliers stop these risks and keep medicines safe. With modern tools and techniques from pharma packaging suppliers, these issues can be managed from the moment a product is packed until it reaches the end user. It helps protect the contents from the outside environment. It also makes sure that the drug remains strong, clean, and ready for use during storage and delivery.

[1] How Pharma Packaging Suppliers Protect Medicines

Most medicines contain ingredients that react to moisture, air, or light. Even a small amount of exposure can change their structure. This can make the drug less safe or not work as it should.

By using packaging that limits air and blocks light, companies can keep their products stable. These packaging methods help maintain the quality and safety of the product until the point of use.

Each type of drug needs a different kind of barrier. Some need protection from moisture, others from heat or air. The better the packaging matches the product’s needs, the longer the medicine stays effective.

Why Container Material Choice Matters

The material used in a package matters as much as the design. For example, tablets and capsules often absorb moisture from the air. If not sealed well, they may break down or lose strength.

Using the right container helps solve this. Common materials include:

- Glass: strong barrier against moisture and air

- Plastics: durable and lightweight with protective properties

- Foil layers: effective in blocking air and water

- Tablets and capsules: need tight sealing to avoid breakdown or loss of strength

- Liquids and injectables: often require advanced containers for extra safety

- Tested barrier materials: measured for how much gas or moisture they let through

Choosing the right option helps keep products fresh and reduces the chance of damage.

Moisture Control: A Core Focus Area

Moisture is one of the most common causes of product damage. Some medicines break down fast when they absorb water from the air. This change in structure can make them weak or even unsafe.

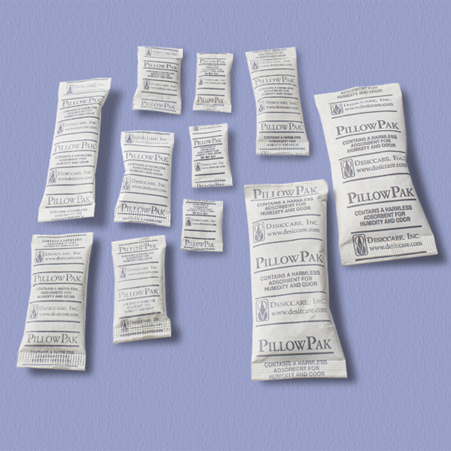

To fix this issue, packaging often includes desiccants. These are moisture-absorbing packets placed inside bottles or blister packs. They help keep the air inside dry and protect the contents.

Other times, barrier films or layered materials are used. These materials stop water vapor from entering the pack. Both methods work to keep the inside dry and improve shelf life.

Protecting Light-Sensitive Formulas

Certain medicines lose their effect if exposed to light. This can happen slowly, but the damage builds over time.

Light-sensitive items are packed in containers that block light. Common tools include amber bottles, dark plastic, and foil wraps. These materials protect the product from harmful rays and help it stay effective longer.

Light-proof packaging is also helpful during transport and storage, where it is harder to control exposure. It adds a strong line of defense that supports product safety at every step.

Sealing Systems and Leak Prevention

How a package is sealed plays a big role in keeping the product safe. If a seal is weak or broken, air and moisture can get in. This can damage the medicine before it is used.

Modern sealing systems now use heat or pressure to close packages tightly. This makes sure there are no leaks and no air can get inside. These seals also stop tampering and protect the product from being changed or spoiled.

Good sealing keeps the medicine safe from its production line to its delivery point. It is one of the last but most important steps in secure packaging.

Labeling That Supports Storage Conditions

Packaging labels are not just for brand names. They give important facts that help keep the product safe.

Labels may list storage temperature, expiry date, and handling instructions. This tells users how to store the medicine in the right way. It also helps avoid damage caused by poor storage.

Clear labels help reduce user mistakes. They guide pharmacies, clinics, and patients in keeping products in good shape until use.

How Proper Packaging Reduces Waste

When packaging is weak, products spoil and must be thrown away. This creates waste and costs businesses money.

By using good packaging, more of the product stays safe until use. This cuts down on expired items and replacement costs. It also helps avoid supply problems.

Packaging that protects well can also reduce how often recalls or complaints happen. This supports a stronger supply chain and a better end-user experience.

Final Words:

[2] At Adsorbtek Solutions Inc., we understand how much shelf life matters. That’s why we offer trusted pharmaceutical packaging solutions in the USA for products that need real protection. Our packaging shields medicines from moisture, light, and air, helping tablets, liquid drugs, and temperature-sensitive items stay safe and effective. We tailor each system to match your needs, backed by tested materials, deep expertise, and on-time service.

Protect your medicines from moisture, light, and air with Adsorbtek’s proven pharmaceutical packaging solutions. Contact us today to extend shelf life and safeguard patient trust.

FAQs:

1. Why is packaging important for medicine shelf life?

It protects the contents from moisture, light, and air, helping drugs stay effective for longer.

2. What materials are used in pharmaceutical packaging?

Common materials include glass, plastic, and foil, chosen based on the product’s needs.

3. How does moisture affect medicine quality?

Moisture can cause chemical changes in medicines, making them weak or unsafe to use.

4. Why do some medicines need light-blocking containers?

Light can break down certain ingredients, so dark containers protect against loss of strength.

5. What role do desiccants play in packaging?

Desiccants absorb moisture inside the package, helping maintain product quality during storage and shipping.